ss / te NORMANDIE starting

from cold

BUILDERS: PENHÖET, St. Nazaire, France

This document is

almost exclusively about the engineering aspects of NORMANDIE, mainly on

how to start her up from cold. If you are looking for photos of the passenger

spaces, there is a plethora of them on the web, in Facebook groups - Admirers of the ss Normandie, ss Normandie photographic file, The French Ocean Liners / Les Paquebots Français, ss Normandie, GREAT LINERS OF THE PAST & PRESENT, and others, Pinterest

and in articles about NORMANDIE here in the blog, please see at the end of the article.

Using "ss" for NORMANDIE is quite incorrect, as NORMANDIE was a Turbo Electric vessel and not a steamship, therefore NORMANDIE should be adressed as "te".

by Earl of Cruise

te / ss NORMANDIE berthed in Le Havre, Gare Maritime May 29th, 1935 - colouring courtesy Daryl LeBlanc

NORMANDIE was, from her inauguration till the end, "the Peak of

Chic".

It was a "must do" for international high society to make a crossing on "Le Vaisseau de Lumière", the Ship of Light, in order to make their mark in Society. During the inaugural crossing of NORMANDIE, "la Deesse de la Mer" was the headquarter of Parisien society ... On board NORMANDIE in the so-called "flirty thirties" could be seen the cream of mid 30s society, and NORMANDIE was the perfect stage on which to be presented and to be seen; even the arrangement and number of staircases on board gave each passenger the possibility for their own grand entrance. NORMANDIE was designed down to the last detail, with every part of that phenomenal vessel built to endure: The hull of the NORMANDIE was designed by Vladimir Yourkevitch, the brilliant Russian emigre. The design was so advanced, that NORMANDIE was able to snatch the Blue Riband with her 160,000hp and maximum speeds over 30 kts, with an average speed of nearly 30 kts. The exterior gave the lines for the future to come, as well as the interior with the lay out concept in the public rooms, cabins and suites. As a first on any Transatlantic liner, NORMANDIE offered a huge number of veranda suites on the promenade deck, where the well-heeled passengers could open their windows to enjoy the bracing Atlantic sea air.

Despite her disastrous ending by fire, NORMANDIE had the

most advanced fire fighting system installed, still innovative today, and if only the incompetent organisation of the refit company had not shut down the vessel systems completely - especially this fire prevention and extinguishing system - the outcome would no doubt have been different.

The vast fire doors on the promenade deck could have withstood the original fire caused by a careless worker; in fact the closed theater was unharmed in the event, to the surprise of the officials. The enthusiasm of the fire brigade sealed her fate by capsize in much the same way as the Empress of Canada in Gladstone Dock, Liverpool.

The dining room was at least the first large air conditioned room on the Atlantic and bigger than the Hall of Mirrors at Versailles. No room since NORMANDIE on any ship was ever that grand and spacious. No restaurant afloat ever offered such such fine food in the best traditions of French Cuisine.

te / ss NORMANDIE, Grand Salle á Manger 1ère Classe - colouring courtesy Daryl LeBlanc

NORMANDIE was the benchmark of luxury in the 30s and

thereafter, as no vessel was ever designed that grand again.

NORMANDIE had a long list of firsts offered on board on the North Atlantic, such as a full blown theatre and cinema, the above mentioned veranda suites, a permanent outdoor pool as well an indoor pool, the air conditioned dining room, and for all classes the egalitarian view of the wake of the ship when underway - no class restrictions there ... After having a tour on board NORMANDIE which included the machinery rooms, Fred Astaire was so impressed that he recreated it as a film set in the film "SHALL WE DANCE". He was so impressed that his machine room film set was made all in white, as were all the machinery rooms of NORMANDIE - spotlessly clean.

te / ss NORMANDIE, dance scene inspired by NORMANDIE´s clean machine room Slap That Bass, SHALL WE DANCE

te / ss NORMANDIE, dance scene inspired by NORMANDIE´s clean machine room SHALL WE DANCE

te / ss NORMANDIE, dance scene inspired by NORMANDIE´s clean machine room SHALL WE DANCE

Not only for the aficionados, NORMANDIE was and is the

perfect ocean liner which has never been equaled. Alongside NORMANDIE, other vessels tended to look old-fashioned and only to be pitied as they tried to emulate the impossible!

te / ss NORMANDIE, dance scene inspired by NORMANDIE´s clean machine room Slap That Bass, SHALL WE DANCE

by Earl of Cruise

|

STARTING te NORMANDIE from Cold

1 Overview of propulsion machinery systems

1.1 General Characteristics (from Engineer & Shipbuilder)

From reasons of stability of working,

efficiency and general robustness as well as absence of vibration and noise,

steam turbines with synchronous electrical transmission were chosen for

propulsion. The propelling machinery is arranged over four lines of shafting,

each driven by a three-phase synchronous motor.

Each propulsion motor normally derives its

energy from one of the four main alternating current turbo-generator sets.

Under conditions of maximum economy and at the normal service speed, the

machinery has been designed for a total output of 130,000shp (96,980kW) i.e.

32,500 shp per shaft, with a propeller speed of 225 rev/min.

Under maximum overload conditions, the

machinery is capable of developing 160,000 shp, i. e. 40,000 shp per shaft at

243 rev/min.

The turbines are supplied with steam at

23.5 kg/cm2 (335lb/in2) pressure and at a temperature of about 325C (617F).

Electrical connection between alternators

and propulsion motors is synchronous except during starting or stopping, when

the propulsion motors function asynchronously. During normal connection in

synchronism, the ratio of speed reduction between the turbo-alternator and the

propulsion motor or motors, which it feeds, is fixed and equivalent to 10:1.

The propeller revolutions are thus regulated in accordance with the speed of

the generator, i.e. in accordance with the speed regulation of the turbine.

During normal running at high speeds each

turbo-generator feeds one propulsion motor only. It is, however, at all times

possible by means of mechanically interlocked isolating switches to feed the

motors of the two line shafts on one side by either of the turbo-generators on

that side, thus giving greatly improved efficiency at reduced powers. In no

case is coupling between the turbo-generator sets provided.

Reversing is very easily carried out with

the aid of throw-over switches, the operation of which modifies the connections

between the current generators (turning always in the same direction) and the

propulsion motors fed by these generators.

The fact that the relative positions of the

generators and the motors are not strictly fixed gives considerable latitude

for instalment. The turbo-generator sets are therefore placed close to the

boilers and the turbines are mounted directly above their individual

condensers, resulting in an important saving in the length of steam piping

required. The propulsion motors are placed in a compartment aft, thus

eliminating long lines of shafting and facilitating also the arrangement of the

watertight subdivision of the ship. This separation of the primary and

secondary machines enables the ship to proceed with all its screws running in

the event of the breakdown of a generator.

The simple operation of two-way switches

suffices to isolate the generator that has failed.

1.2 Methods of propulsion generator operation:

1.2.1 Normal Operation:

Four turbo-alternator sets in use providing

an output of 130,000 shp with the speed of rotation of alternators and

propellers respectively being 2,250 and 225 rev/min, a reduction ration of

10:1. One turbo-alternator per shaft.

1.2.2 Maximum power:

Four sets in operation at 160,000 shp, with

corresponding revolutions of 2,430 and 243rev/min respectively. One

turbo-alternator per shaft.

1.2.3. Cruising:

For lower intermediate speeds the following three seperate combinations have been provided:

(a) The four turbo-alternator sets runninig at reduced speed, each feeding its own line shaft.

(b) Two turbo-alternator sets running at reduced speed, each feeding the propulsion motors on two line-shafts with the normal propellers fitted (see c below). The power obtainable is about 60,000 shp normal output at 1,750 rev/min, and 70,000 shp continuous overload at 1,840 rev/min.

(c) Two turbo-alternators running at reduced speed, each feeding the two line shafts. Under this condition special propellers are fitted to give 80,000 shp at about 2,360 rev/min for economical running and about 88,000 shp at 2,400 rev/min under continuous overload.

During the night from June 1st to 2nd NORMANDIE averaged 30,2 kts using only 128,000 hp of indicated 160,000 hp and made up time for a sea water intake in the condensers.

Despite NORMANDIE averaged at 29,98 kts for the 2,907 sm trip from Bishop Rock to Ambrose lightship and reduced the travelling time to 4 days, 3 hours, 2 min.

by

Earl of Cruise

|

The above being an extract from the builder´s information sheet, we will now go on board the NORMANDIE and start her up from cold. For this we need a handful of firemen to start up the requisite boilers, and possible a few junior engineers to help us with the auxilliary machinery. Let´s take a taxi to the ship and have a look around ...

We arrive at the quay and the ship is towering

above us, dark and quiet - no lights or smoke from the funnels as there is no

power on. She looks good though, a true Queen of the North Atlantic - it seems

there is already someone on board waiting for us to get her going.

"Dark and Quiet" te / ss Normandie 29 May 1935 in Le havre Gare Maritime - editors collection

We walk up the gangway and into the First

Class entrance, starboard side on A Deck. Normally we would use the crew

gangway to avoid mixing with the passengers, but today we can have a quick look

at the opulence of this magnificent liner as we pass through to our first task -

starting the emergency diesel generators - so we will use the imposing main

staircase to get from A deck to the Upper Deck.

I hope our engine room boots are clean ...

I hope our engine room boots are clean ...

te / ss NORMANDIE, the Entry Port on A Deck - copy from The Shipbuilder, editing by Stephen Carey, complete deckplan

te / ss NORMANDIE, the Entry Port on A Deck - copy from The Shipbuilder, editing by Stephen Carey

te / ss NORMANDIE, the Entry Port on A Deck - copy from The Shipbuilder, editing by Stephen Carey

We pass in through the main doors, past the

lifts (we can’t use them as there is no electricity) and walk forward to the

staircase and take the starboard side stairway to the Upper Deck.

We pause to admire this area, which is the main entrance for the more wealthy amongst us to access their cabins and de-luxe apartments, before carrying on up the starboard side of the Grand Stairway to the Promenade Deck - before we get found out loitering in places where we shouldn’t really be -

Take a look around, behind us ...

We pause to admire this area, which is the main entrance for the more wealthy amongst us to access their cabins and de-luxe apartments, before carrying on up the starboard side of the Grand Stairway to the Promenade Deck - before we get found out loitering in places where we shouldn’t really be -

Take a look around, behind us ...

te / ss NORMANDIE, Grand Halle 1ère Classe, Promenade Deck - colouring courtesy Daryl LeBlanc

That´s rather nice, Icould live here under the "vestibule dome" ...

te / ss NORMANDIE to get a glimpse of the dimensions of the Grand Halle 1ère Classe, Promenade Deck - editors collection

te / ss NORMANDIE, WOW! Le Grand Escale, Hollywood and Las Vegas copied this staircase for the grand entrance - colouring courtesy Daryl LeBlanc

te / ss NORMANDIE, Le Grand Salon - colouring courtesy Daryl LeBlanc

Let’s press on ...

te / ss NORMANDIE, Promenade Deck and Emergency Generator Room - copy from The Shipbuilder, editing by Stephen Carey

Exiting out of the starboard side forward

Promenade Deck door, we walk forward past the huge theatre and open the doors

to the emergency generator room for which we have a key, which unauthorised

persons don’t. You can look over the side from here at the people on the

quayside waiting for the lights to come on, so look important and be well

dressed …

te / ss NORMANDIE in Le Havre, Gare Maritime 1935 - colouring courtesy Steve Walker

3 Getting started

3.1 The Emergency Diesel Generators

The Emergency Generator Room houses two MAN diesel generator sets of 150 kW each at 220 Vdc. These engines are compressed air started, with all auxilliary pumps such as cooling water, cooling fan, fuel, lubrication oil, etc. driven by the engine to make them completely self-contained, pretty much like your car. They are also situated high up in the ship to ensure they are not in an area susceptible to damage.

The generators are automatically started when the electrical system senses no voltage on the main bus (the "main bus" means main busbars, which are in effect the live and return cabling similar to that on a car, though the return is not attached to the ship´s side like a car system). However, the switch which would normally start the engines is not in the auto position, so by switching it across, we could allow the engine to start automatically, but this is a bit risky as it is supplied for "warm start" when the main generators fail for whatever reason. We are cold starting, so have to be careful not to damage anything.

Before we start, we have to check the engines over for a sump level, water tank level, battery voltage (for control system) in the same way as you would a car, followed by barring the engine over on the turning gear to make sure there is no water in the cylinders. Having done all that, we can open the fuel valve on the diesel tank within the room and check that the starting air recievers have enough air in them to start an engine. We assume here that they do, otherwise we have a bit of a problem ... Before starting, we need to manually prime the lube oil system, as the engine probably hasn´t run recently. We work the hand pump on the engine until a pressure is shown on the oil pressure gauge.OK,

OK, make sure your earmuffs are on

(probably not available in 1935, but we can do our bit to save our ears - these

things are noisy!) and press the start button. This will energise the starting

air valve solenoid and admit high-pressure air from the air receivers into the

cylinders to rotate the engine.

te / ss NORMANDIE, Figure 7, one of the two MAN 150 kW Emergency Diesel Generators - copy from The Shipbuilder

The engine turns on compressed air and

fires on fuel, running up to speed on the governor. It’s certainly noisy, which

is why it is as far as possible from the cabin accommodation and has insulated

bulkheads. We let the engine settle down and run up to working temperature

before we close the breaker onto the emergency switchboard, which is located in

the same room. Looking at the switchboard we see a number of breakers that will

allow us to feed emergency power to certain sections of the ship. It would be

easy to close them all, but as we need to start up the main boilers and

generators, we need to conserve power to only the necessary lighting to allow

us to see what we are doing in the engine and boiler rooms. We have 300kW

available though; enough to start a 77hp Forced Draft Fan and a 16hp fuel oil

pump for one of the main watertube boilers. As there are 746W to a hp, that equates

to 57kW for the fan and 12kW for the oil pump, a total of some 70kW - half a

generator gone already! However we now know that on one generator we can start

up at least two boilers, with the other generator available for lighting and

anything else we need to start in order to get steam on the main

turbo-generators, such as lube oil pumps, feed pumps etc. We are in for a long

day …

The boiler room fans are on the emergency

circuit via the main bus, as can be seen from the ship’s single line diagram

(SLD) - right hand side, reproduced below. We will see the left hand side of

this drawing later -

te / ss NORMANDIE, Figure 8, Emergency side of Single Line Diagram - copy from The Shipbuilder

Here you can see circled at left, the

boiler room fan breakers, which we will need to close, and also the boiler room

pumps breaker (via the engineroom pumps panel) to put power on for the oil

pumps. However these breakers are off the main bus, so we will close those

later when at the main switchboard down below. For now we just close the

emergency feed to the main bus systems via the interlocking switch. As if by

magic, the emergency lights come on!

Top right on the drawing can be seen the

two emergency generators, the emergency switchboard and the 24V control

switchboard. With these breakers closed, we can work our way down to the bowels

of the ship and make her come alive.

Before we leave the EDG room we check the

levels in the emergency generator fuel tanks - great, 24 hours at least, though

we won’t need them for that long - and make sure the battery charger is working

on the control system. This is important because once switched to auto, the

emergency generators will automatically battery start on loss of power on the

main bus and put themselves on the board to provide lighting - besides the

passengers not liking being in the dark for more than a few seconds, items such

as navigation lights, steering gear and radio operate off the emergency

generator. In this ship with 6 main generators and 29 boilers, there is so much

redundancy that a “black out” is a very remote possibility.

Let us now proceed to the boiler rooms and

engine rooms for a look round. As this is a fancy passenger ship, you can wear

your company cap with your uniform if you like, in case we run into the Chief

Engineer, though I will wear a boiler suit in case I get dirty. No hard hats

are necessary as no one is likely to drop anything on our heads and in any

case, PPE isn’t invented yet; we even have to buy our own uniforms, boilersuits

and boots, as it will be some decades before owners buy them for us. Union

Power ...

3.2 Going "Down Below"

To get to the machinery spaces we have a

long way to go and there are several ways of getting there. We will head down

the staircase forward of the theatre and go down the restricted staircase for

the crew access to each deck. This turns out to be an enclosed white-painted

shaft going down and down. And down. Our boots echo on the stairways in the

silent ship, with the faint hum from the EDG gradually disappearing as we go

down through 6 decks to E Deck, to a door which says something like “Aucune admission au personnel non autorisé”,

but we are authorised personnel and we go through the door into the fan area

above the silent forward boiler room. Here we can see the forced draft and

ventilation fans ready to supply air to the boilers. Again our boots clatter on

the rungs of the ladders down to the boiler room floor plates, where we stand

in amongst the main power generation equipment of this huge liner - the steam

generating plant main boilers in the forward boiler room. There is a faint

smell of new paint and fuel oil in the air, which all boiler rooms have, given

off by the fuel pumping plant and hot lagging round the steam pipes once steam

is raised - this room is as big as a cathedral; a cavernous echoing space. Take

a moment to look around you and up into the uptakes above us.

te / ss NORMANDIE, Figure 9, Down - down - down below - collection Stephen Carey, complete cutaway

3.3 Boiler rooms

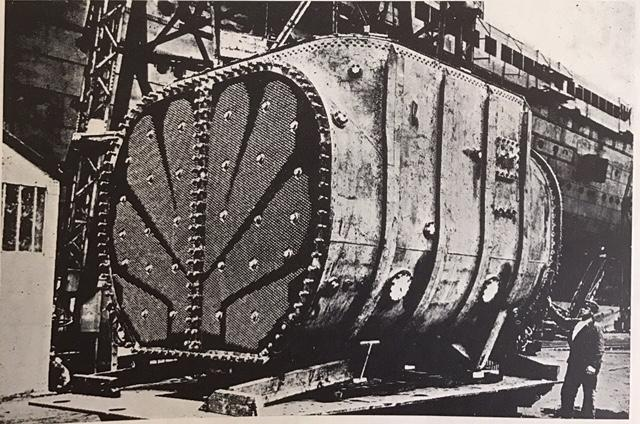

NORMANDIE has four boiler rooms arranged from forward to aft, containing 29 water tube boilers and four Scotch boilers.

The boilers in this boiler room and auxilliary machinery items are arranged as follows - figures in colum 1 show the plate reference numbers for the drawings that follow. It is best to print a copy of the plates as a reference when going through the tables and for the walk-round we are doing.

3.3.1 Boiler Room 1: Ref.

|

Qty

|

Designation

|

A1 to A4

|

4

|

Main water tube boilers

|

C

|

2

|

Main oil-firing units

|

D

|

2

|

Underwater sewage ejectors

|

E

|

3

|

Main forced-draft fans

|

F

|

2

|

Ventilating fans

|

te / ss NORMANDIE, Figure 10 Boiler Room 1, Plan - copy from The Shipbuilder

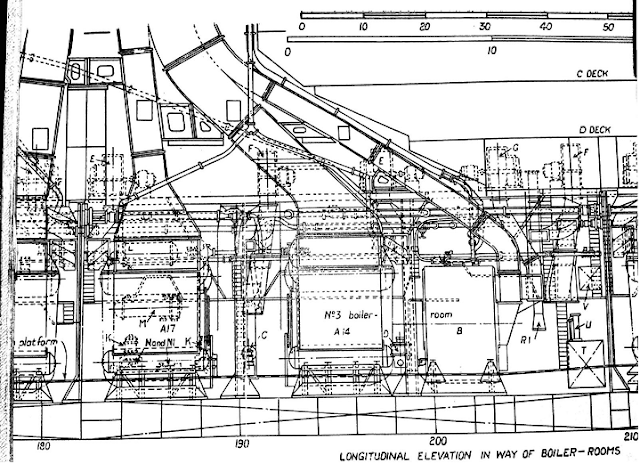

te / ss NORMANDIE, Figure 11 Boiler Room 1, Elevation - copy from The Shipbuilder

We will pause here to start firing the

boilers, as it is usually better on a dead ship to light the forward-most

boilers first, with the main stop open to the main steam lines in order to

bring up these lines - which pass right through the watertight bulkheads to the

turbo-generator rooms - together with the boiler rising pressure. In this way,

the main steam lines can be warmed through and drained of condensate, which

would otherwise damage the steam turbine machinery. There are drains on these

lines at various points along the length of the piping.

We need firemen for this job, and they are

luckily on hand waiting for us to give the go ahead.

From the view below, you can see that the

boiler room is in immaculate condition, unlike the stokeholds of the coal

burners in the earlier ships of this series of cold-starting notes. We will

open the drains and “steam traps” as we walk through the spaces. A steam trap

will allow automatic draining of condensate from lines to negate having to

stand and watch them whilst they are draining, though there is a bypass to

allow quick - attended - draining; wasting feedwater/condensate is frowned upon

on steam ships. Condensate or “condensed feed water” is liquid gold on a steamship,

so these drains are collected in tanks and returned to the feedwater tanks.

Most steam engineers even begrudge the Master using the steam whistle overmuch!

te / ss NORMANDIE, Figure 12 Boiler Room 1 - editors collection

Here you can see yourself facing forward in

your smart uniform checking out the general condition of the boiler systems. To

your left (port side) is the oil-burning pump set for these boilers, which we

will soon be starting up. In front of and behind you are two of the boiler

fronts, with the four square burner panels visible on each, along with the

white-lagged fuel rail. You can see the lagging on some of the steam pipes, and

the white circular covers over the bottom drums of the watertube boilers. The

fuel oil heater - the black drum - can be seen in the background, and there are

two more boilers to your right (starboard).

We use a boiler room phone to call the main

switchboard (where an electrical engineer is in attendance) and ask him* to

close the breakers for the forced draft fans and the oil pumping systems in this

compartment.

*Note:

|

There was only

one female engineer at sea in those days, and not on this ship either as she

was ashore in 1935 running a business with her sister - see Victoria

Drummond.

|

We then instruct the firemen to start up

the boiler oil pump and start circulating the oil from the fuel oil settling

tanks to the pump suction strainers and into the pump, which then discharges

through the heater. The firemen will use the small electric heater and pump

unit for starting the system because we have no steam available for the main

heater; it’s known as a “cold start” pump and heater. Hot oil is now available

at the boiler burner rail. The pump pressurises the rail to around 16bar by

means of a pressure-regulating valve (PRV), to ensure that the burner rail

pressure remains constant at all times. From the PRV the fuel goes back to the

pump suction upstream of the heater. The pump capacity is some 16.7m3/hr or

15t/hr, which is 360t per day delivery, though actual consumption would be less

than that. Here’s a sketch of a typical boiler fuel circulation diagram -

te / ss NORMANDIE, Figure 13 Typical boiler fuel oil circulation diagram

The fuel comes from the settling tank and

via a suction strainer into the fuel pumps, which discharge it through the

heater and fine filter to remove any impurities that may block the burner tips.

Whether Normandie had a Viscosity Regulator is not known, but this device if

fitted would measure the fuel viscosity and either increase or decrease the

heat applied by the heaters. Normandie didn’t have a diesel supply for cold

start either or, if she did, it’s not mentioned in any publication. The fuel

then enters the fuel rail which supplies all the burners in the boiler system,

with a spur to the other boilers supplied by the same pumping system. The

pressure builds up in the line, and is vented via the back-pressure valve - or

a manual valve as shown in the diagram - back to the pump suction. It is likely

that with so many boilers, Normandie would have an automatic pressure regulator

to keep the fuel pressure steady at 16bar.

Whilst this is happening, we climb the

ladders to the top of the boilers in the forward boiler room and open the main

stops, which are the isolation valves from the steam drum and superheater. At

the same time we open the superheater-starting valve so that when steam is

raised there is a path through the superheater tubes to avoid them overheating

before we can get a turbo-generator running (this is just a valve that leads

the steam to the bilge - it makes a racket, though is sometimes fed through a

silencer). We then go to the electric starter for the forced draft fans “E” and

the ventilation fans “F” and start them up - it’s quite noisy and we have

trouble hearing each other once they are going. The fan speed can be regulated

to match the draft with the oil quantity to allow smoke-free combustion - and

the firemen will control the oil and air volumes to the furnaces as required.

As we are starting up from cold, it will take some hours to gradually raise

steam on the boilers. We will start with around ten minutes of firing every

half hour and gradually increase this as the boilers warm through and start to

make steam. Raising steam too quickly could cause thermal shock to the boiler

internals, which is obviously to be avoided. The Leading Fireman knows what he

is doing, and we can leave him to do the job.

te / ss NORMANDIE, Figure 14 fireman tending the fires on the burner front - editors collection

te / ss NORMANDIE, Figure 14 a fuel oil pump (one of ten) - editors collection

The fireman’s job is a lot easier on an

oil-burner compared to a coal-burner in that he doesn’t have to shovel coal,

discharge huge quantities of ash or clean fires every watch, which is a filthy

job and very labour intensive. Our fireman above is firing using one of the

main burners to warm through, and will cycle through them one at a time to warm

the internal brickwork and tubes up evenly. With careful control of the

combustion air and fuel, he can ensure a clean flame which is not only more

efficient in burning the oil, but also keeps the boiler internals clean which

aids in the transfer of heat from the flame to the water tubes. Dirty tubes can

cause local hot spots, which can result in a tube cracking or bursting. Even on

an oil-burner the fireman’s job is still very important and it takes a skilled

man to watch the water levels, steam pressure and flame condition. He also has

to know when to withdraw a burner and replace it with a clean one if the oil

vaporisation is starting to get ragged. This would cause excessive smoke, which

is to be avoided for both boiler condition, fuel economy and passenger comfort!

The silence in the boiler room is now a

thing of the past - the noise of the forced draft fans and ventilation fans

fills the room, the roar of the flame inside the boiler and the flickering

light through the furnace sight glass is evident in all the fired boilers. The

fuel-pumping unit is humming away feeding the furnaces with fuel, and there is

a smell of hot lagging permeating the space. We are starting to get things

going and will move aft through the other boiler rooms to the turbo-generator

room and propulsion room.

Note:

|

The term

“turbo-alternator” is used for this ship only for the propulsion units, as

they are synchronous units - i.e. alternating current. Nowadays the term

“alternator” is relegated to automotive use, marine systems being termed “AC

Generators” or “DC Generators”. The book used for information terms these

“turbo-alternators” and “turbo-dynamos” respectively, so we will stick to

this terminology as used on the ship in service. The term turbo-generator is

used when generally referring to all the generating machinery.

|

After checking that all is well in Boiler

Room 1, we walk aft through the watertight door into Boiler Room 2, leaving the

heat and noise behind us and into a relatively quiet area.

Again the firemen are standing by, and we

instruct them to start warming through in the same way as Boiler Room 1, but in

this case we leave the stop valves shut to the main steam piping.

In the drawings that follow, we can see

that the equipment in No 2 is similar to that in No 1, though there are 9 main

boilers in the space, so it is much bigger. In fact, it’s enormous and seems to

go up and up forever above the boiler uptakes

The oil-pumping unit in this boiler room is

situated between boilers A8 and A11, and there are six forced draft fans plus 4

ventilating fans to be started in this room. However, we don’t have enough

power to start all these, so will use one set to get each boiler warmed through

and up to pressure against the stop. If this is too much for the emergency

generator, we will leave these units until we have a turbo-dynamo running,

which will allow us to start up all the boilers - there’s no rush!

Notice the “snake-pit” of piping above the

boilers in this room. There are four main steam lines, and the “omega bends” in

the piping are there to allow for expansion as the superheated steam passes

through the lines. You can see where these four lines pass through the after

bulkhead into Boiler Room 3.

3.3.2 Boiler Room 2

Ref

|

Qty

|

Designation

|

A5-A13

|

9

|

Main boilers

|

C

|

3

|

Main oil-firing units

|

F

|

4

|

Ventilating fans

|

H

|

1

|

Ballast pump (10t)

|

I

|

1

|

Bilge pump (300t)

|

J

|

1

|

Wash-deck and fire-main pump

|

Besides the main boilers, ventilating fans

and oil-firing units in this space, we can take a few moments to look at the

ballast pump “H” at the forward end of the room just off the centreline to

port, and the bilge pump “J” on the forward bulkhead starboard. The ballast

pump is used to pump seawater in and out to balance the ship for list and trim,

and it may be that in this ship, and judging by the small capacity of this

pump, the fuel tanks were used for ballast when empty of fuel in order to keep

the trim constant. This once common method of “seawater compensation” is now

out of the question owing to the risk of polluting the oceans with oil.

The bilge pump is used to pump the contents

of the bilges out over the side. The bilges are the lowest part of the

machinery spaces and the bilge wells normally occupy a portion of the double

bottom, thereby allowing any oil, fuel and water drains to end up in the lowest

point of the ship, from where it can be pumped overboard.

Note:

|

Nowadays it is

forbidden to pump bilges or any oily waste overboard from ships unless it has

passed through an Oily Water Separator first, to ensure that anything that

does go over the side is at less than 15ppm oil in water. Bilge tanks are now

supplied such that all drains can go to separate tanks, which make the bilges

a lot cleaner than they were in 1935, though on a prestige liner such as

Normandie it is likely that the Second Engineer will keep the bilges as

pristine as the floor plates shown in the photographs.

|

te / ss NORMANDIE, Figure 15 Boiler Room 2, Plan - copy from The Shipbuilder

te / ss NORMANDIE, Figure 16 Boiler Room 2 – Elevation - copy from The Shuipbuilder

We’ll carry on with our walk through the

boiler rooms into Boiler Room 3. Again the room is enormous and houses a mass

of machinery. There are 5 main watertube boilers in this space, plus 4

cylindrical Scotch fire-tube boilers of which more later. Again we will not

fire the boilers in this space owing to lack of power, so will have a look at

the general machinery lay out as we walk through the watertight door at the

after bulkhead.

3.3.3 Boiler Room 3 Ref

|

Qty

|

Designation

|

|

A14-a18

|

5

|

Main boilers

|

|

B

|

4

|

Scotch cylindrical boilers

|

|

C

|

2

|

Main oil-firing units

|

|

D

|

2

|

Underwater sewage ejectors

|

|

E

|

4

|

Main forced draft fans

|

|

F

|

4

|

Ventilating fans

|

|

G

|

2

|

Forced-draft fans for Scotch boilers

|

|

I

|

1

|

Bilge pump (300t)

|

|

K

|

2

|

Transfer pumps

|

|

L

|

2

|

Hot-water tanks

|

|

M

|

4

|

Saltwater

heaters

|

|

N

|

2

|

Circulating

pumps for hot fresh water

|

|

O

|

1

|

Oil-firing

unit for Scotch boilers

|

|

P

|

4

|

Evaporators

|

|

Q

|

2

|

Evaporator

feed units

|

|

R

|

1

|

Reheater

for Scotch boilers

|

|

S

|

2

|

Feedwater

pumps for Scotch boilers

|

|

T

|

1

|

Lower

secondary feed tank

|

|

U

|

1

|

Secondary

feed filter

|

|

V

|

1

|

Upper

secondary feed tank

|

|

W

|

1

|

Air pump

|

|

X

|

1

|

Circulating

pumps for auxiliary condenser

|

|

Y

|

1

|

Auxiliary

condenser

|

|

Z

|

1

|

Pump and

tank for filter

|

|

R1

|

1

|

Ash hoist

|

|

N1

|

2

|

Circulating

pumps for hot salt water

| |

In 1935 it was the practice to discharge

sewage straight over the side of the ship, and this practice continued for many

years after until the MARPOL (Marine Pollution) Act was ratified around the

late ‘70s. In this compartment there are two sewage ejectors “D” which discharge the sewage away from the ship

underwater. This is a lot better than discharging it on the waterline though,

where sewage discharge could end up in one of the tenders carrying passengers

ashore … There is one sewage ejector to port, and one to starboard.

The Transfer

Pumps “K” situated

port aft inboard of boiler A18 are used to pump boiler fuel from the storage

tanks to the settling tanks. These tanks can be seen outboard, port and

starboard, forming the double sides of the machinery spaces.

When the oil is bunkered from a barge,

there is water and contaminants in it, which would affect the burning of the

oil and tend to block the burner tips. Whilst it is not necessary to clean the

oil to any great degree (as would be required for a diesel engine for

instance), the oil in the settling tanks allows water and dirt - which are

heavier than the oil - to drop to the bottom of the tank clear of the suction,

from where it can be “sludged off” by opening a sludge cock. The suction

strainers and discharge filters of the oil-burning units remove any further

impurities from the oil (Figure 13).

The hot

water tanks, seawater heaters and pumps “L”, “M”, “N” are for domestic

use. Ships of this vintage normally had salt-water baths for lesser mortals, which

were actually rather nice, like a hot spa! They used special saltwater soap as

normal soap won’t lather in seawater. A large jug of fresh water was provided

(by your steward) to pour over yourself afterwards to rinse off the salt suds.

The pumps pressurise the water mains throughout the ship, and also supply

seawater for flushing toilets and urinals. Fresh water baths and showers were

probably also available in First Class, but we don’t need to concern ourselves

about that, other than to make sure the fresh and salt water hot water

circulating pumps are running once we get on to main power. The stewards get a

hard time of it from passengers if there is any malfunction in the water

supplies and temperature, which is rather unfair to them as it all comes from

the engineering department!

The evaporators

“P” are used to make fresh water out of seawater, using steam to

evaporate the seawater with the steam given off being condensed via cold

seawater in a shell and tube cooler. The water so produced is very pure, and is

used solely for boiler water where purity is paramount, especially in watertube

boilers. Domestic/fresh water would be bunkered from ashore in each port, as

the ship was only intended for transatlantic crossings, though the evaporators

could augment this. Nowadays ships have a fresh water generator, which produces

fresh water more economically via flash evaporation (using waste heat and

vacuum) or reverse osmosis.

The remaining feed heaters and equipment

are for use with the Scotch boilers, of which more later.

There is an ash hoist “R1” in this

compartment, but as this ship was built as an oil burner, it’s not clear what

this is for - resistance to change? Plus ça change …?

te / ss NORMANDIE, Figure 17 Boiler Room 3, Plan - copy from The Shipbuilder

Figure 18 Boiler Room 3, Elevation - copy from The Shipbuilder

Again, we will not be starting anything up

in this boiler room until we are on main power, so we will walk the length of

the space and exit via the after watertight door. Note that in ships such as

these, the watertight doors are open all the time in order to allow working

access to the spaces. In the event of damage, they can be closed in a few

minutes to seal off the spaces from each other to lessen the effects of

flooding in any compartment. Access to and egress from the spaces is then by

ladder to the upper decks.

Exiting out of Boiler Room 3, we come to

Boiler Room 4, another huge space containing no less than 11 watertube boilers

- 9 in three rows of three forward, and two at the after end, port and

starboard.

3.3.4 Boiler Room 4 Ref

|

Qty

|

Designation

|

A19-A29

|

11

|

Main boilers

|

C

|

3

|

Main oil-firing units

|

D

|

2

|

Underwater sewage ejectors

|

E

|

8

|

Main forced draft fans

|

F

|

4

|

Ventilating fans

|

R1

|

1

|

Ash hoist

|

S1

|

6

|

Main feed pumps

|

T1

|

2

|

Feed pumps for turbo-generators

|

U1

|

4

|

Main low-pressure feed heaters

|

V1

|

4

|

Main high-pressure feed heaters

|

W1

|

4

|

Coolers for main drains

|

X1

|

1

|

Low-pressure feed heater for turbo-generators

|

Y1

|

1

|

High-pressure feed heater for turbo-generators

|

Z1

|

1

|

Cooler for turbo-generator drains

|

te / ss NORMANDIE, Figure 19 Boiler Room 4, Plan - copy from The Shipbuilder

te / ss NORMANDIE, Figure 20 Boiler Room 4 - Elevation - copy from The Shipbuilder

In this boiler room are situated parts of

the feedwater system, which will be discussed later as we start to energise the

main equipment ready for sea. Otherwise the equipment is more or less the same

as in the other boiler rooms.

A few notes on the fuel oil arrangements of NORMANDIE

3.3.5 Oil bunkers

The boiler oil fuel bunkers are arranged in

the double sides outboard of the boiler rooms, and comprise 12 storage tanks on

the starboard side, and 13 storage tanks on the port side. There are 4 settling

tanks inboard of the storage tanks outboard of Boiler Room 3. The latter

separate oil from water and other solids by gravity, and are regularly sludged

to remove the water prior to it being pumped to the boiler oil-firing

apparatus. The oil-firing or burner pumps are arranged between each pair of

Yarrow boilers.

3.4 Turbo-dynamo, turbo-alternator and auxiliary engine room

Continuing our walk through the ship, we

exit via the watertight door in the aft bulkhead of boiler room 4, and find

ourselves on the lower level of the turbo-dynamo and turbo-alternator room.

This is another large space containing a mass of machinery, all of which

supplies electrical power for propulsion as well as hotel and other services.

The main rooms are on two levels, so we will go up the stairs to the upper

level, eventually moving aft to the main switchboards and the manoeuvring

platform, from where the engines are controlled. This is a nice clean space,

light and airy, with the machinery well kept and painted in light colours to

improve visibility. It’s silent at the moment, apart from the odd drip of

seawater into the bilges from leaking pump glands and valves, but otherwise

“the calm before the storm” once all ten turbines are running. We will start a

ventilation fan for this space, and hope that the emergency generators won’t

trip… (Well, the lighting flickered a bit, but we didn’t trip the generators,

so all well and good!)

te / ss NORMANDIE, Figure 21 Engineer Officers in the turbo-dynamo room - editors collection

The picture shows the engineering staff

standing between the two inboard turbo-dynamo units. These are the units that

supply main power to the switchboards for our machinery systems, but are not

the power units for propulsion. Even so, these are large items of equipment,

and there are six of them in this compartment. The large piping in the form of

a “suitcase handle” at the end of the room are the exhaust bends from the hp to

the lp main propulsion turbines which make up each turbo-alternator unit, so we

are facing aft in this photograph.

Another photograph of the space without the

engineers shows the sheer size of the generating units, which stretch the whole

length of the room. Again the exhaust bends of the propulsion alternator turbines

can be seen in the distance at the after end of the room.

te / ss NORMANDIE, Figure 22 Turbo-dynamos with Propulsion units aft - editors collection

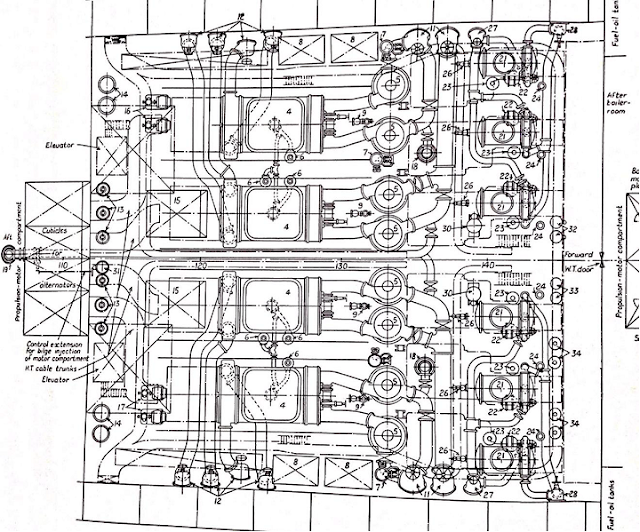

Situated aft of Boiler Room 4, this room

contains the electrical power generation machinery and auxiliaries.

For all electrical services, 6

turbo-dynamos are fitted (shown within the green rectangle, Figure 23). Each

dynamo is driven by a steam turbine prime mover and comprises 6 sets of hp and

lp turbines, condensers, circulating pumps, condensate pumps and vacuum

augmenters. These are the units that we will be shortly starting up, in order

to get us from emergency power to main power. We can spend some time getting

things ready in this area whilst we wait for the boilers to come up to

pressure.

Also in this room at the after end are the

four turbo-alternators (shown within the blue rectangle), which are the

propulsion units, of which more later. The equipment installed in this

compartment at the forward end between Frames 135-145 is tabled after the

drawings of the Lower Platform Level.

te / ss NORMANDIE, Figure 23 Turbo-generator Room, Upper Platform Level Plan - copy from The Shipbuilder, editing by Stephen Carey

Having a look round here, in conjunction

with the picture taken looking aft shown earlier, we are standing just above

the steps down into the propulsion alternator space, with the two inboard

turbo-dynamo units either side of us. Now that a ventilation fan is running you

can see where the air is distributed on the drawing above, by the arrows shown

on the trunking. It’s adding a bit of noise to the space and you can feel the

air circulating through the room.

Our first job here is to go back down to

the lower platform level and start attending to the auxiliaries we need to get

a turbo-dynamo going.

te / ss NORMANDIE, Figure 24 Turbo-generator room - lower platform level Ref - copy from The Shipbuilder

Qty

|

Designation

|

|

20

|

6

|

Turbo-dynamo units

|

21

|

6

|

Condensers

|

22

|

6

|

Circulating pumps

|

23

|

6

|

Condensate pumps

|

24

|

6

|

Vacuum augmenter

|

25

|

1

|

Hotwell tank

|

26

|

6

|

Feed regulators

|

27

|

2

|

Sea induction valves

|

28

|

2

|

Seawater overboard discharge valves

|

29

|

6

|

Returned oil tanks

|

Down here you can see at the forward end,

the watertight door that we came through from the boiler rooms. There is a mass

of machinery and piping in this area, all of which is to serve the

turbo-dynamos (20). Slung under the turbines we saw on the upper level are the

condensers (21), one for each turbine unit. These are provided to condense the

steam issuing from the exhaust of the turbine sets in order to drop the

pressure and extract the maximum energy from the steam. To achieve this vacuum,

the steam passes round a tube bundle in the condenser (21) through which passes

cold seawater, which condenses the steam into condensate, which drops to a well

at the bottom of the condenser. We will get things going here by starting one

seawater pump (22), but before we do that we have to go outboard to the

seawater inlet and discharge valves and open them up. We crack open the

discharge first (28), and then open the inlet valve (27) fully. Going across to

the seawater pump starter, we press the start button (which starts the pump at

low revs) and gradually increase the speed. Whilst you are doing this, I open

the discharge valve fully (the reason for throttling the discharge is so that

the centrifugal seawater pump starts on no load). The pump runs up to full

speed and we check that the seawater pressure is satisfactory on the attendant

gauges for suction and discharge pressure.

te / ss NORMANDIE, Figure 25 Dynamo condenser seawater circulating pump - editory collection

There is another item, which is the “vacuum

augmenter” (24), otherwise known as a vacuum pump, whose purpose is to remove

non-condensable gases from the condenser, mainly air and CO2 in order to

improve the vacuum created by the condensing steam. For this to work however,

we need steam, so we check with the main steam line pressure gauge to see if we

have pressure up on the line. As it’s some time since we fired the boilers up

forward, we find that the steam pressure is indeed now up to 28kg/cm2 in the

main lines. This is a much higher pressure than the earlier ships of the

series, and the superheaters in the boilers will raise the temperature of the

steam above saturation temperature to 350C. The temperature of dry saturated

steam at this pressure is 231C, so this corresponds to 119 degrees superheat

(i.e. degrees above saturation temperature). Superheating makes the energy

delivery more efficient, and the steam is dry, with no condensate forming once

the lines are up to temperature.

te / ss NORMANDIE, Figure 25 a sectional arrangement of Turbo-generator - copy from The Shipbuilder, editing by Stephan Carey

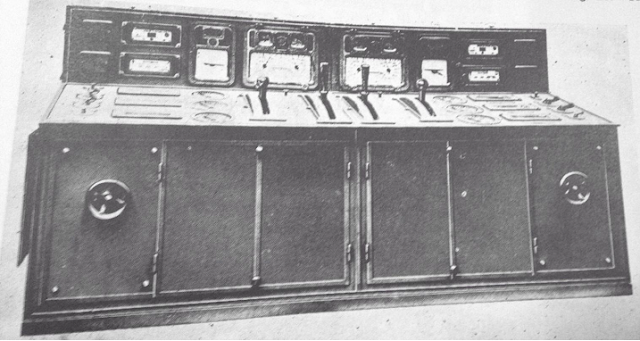

Here we see a longitudinal section of the

turbo-dynamo. On the right is the turbine driver with its control valve (on the

end at the top), governor and gland steam system.

The turbine blading is encased in the

“cylinder”, with steam passing and expanding through the blades from right to

left, such that it drops in pressure at each stage, finally exhausting to the

condenser at a vacuum (induced by the condenser as mentioned earlier).

In the centre is the single reduction

gearbox, which reduces the turbine speed at the input down to the generator

speed at the output, from 5180 to 530rev/min, or a reduction ratio of around

9.8:1.

To the left is the actual electrical

generator, whose rotor and stator produce 220Vdc at the terminals. This

turbo-dynamo produces a full load power of some 2.2MW, so it and its other 5 fellows

can produce 13.2MW, though four are used in service with two spare.

4 Starting a main turbo-dynamo

Starting the turbine for the first dynamo

we will be putting on the switchboard is a bit of a juggling act. We have to

make sure the steam is dry to avoid damaging the blading; we have to start

auxiliary pumps (with limited emergency power as mentioned earlier); we have to

start steam auxiliaries such as feed pumps and condensate pumps (23). We have

already started a seawater pump above, and this is consuming 39.8kW of our

emergency generator supply. We need main power as soon as possible.

First we go to the main steam stop valves

on the forward bulkhead and check the drains to ensure there is no water in the

lines. Up forward the firemen are standing by on the fires ready for us to

start using steam. As steam is used in the generator, the boiler pressure will

start to drop so the firemen will keep an eye on the boiler level, the steam

pressure (maintained by adding more burners if required) and closing the

superheater starting valve once the generators are running on superheated

steam. This valve is blowing off to the bilge all the time the boilers are

fired; it makes a racket and is a blessed relief once it’s closed.

A typical generator start up routine is -

1. Check that we have a small amount of

water in the bottom of the condenser to ensure that the condensate pumps will

have suction. The condensate pumps draw water from the condenser as it evolves

from the condensed steam. The level in the condenser is maintained by an

automatic regulator that works off the condenser level, returning the water to

the condenser or to the feed tanks as required. If there is no water (we will

assume there is) more can be added from the feed tanks or heaters under gravity.

2. Re-set the emergency governor. This will

have been tripped to stop the generator when it was last used.

3. Open all drains (main steam stop valve, turbine cylinder, main steam strainer).

This will ensure there is no water collected in the cold piping as it comes

into contact with the steam from the main lines.

4. Start condenser circulating water plant

(seawater pump), which we have already done

5. See that the motor-driven oil pump

starter switch is in “on” position. Start the pump and allow the oil to

circulate through the turbine, gearbox and generator bearings. Once we are up

to speed, the engine-driven LO pump will supply the pressure, and this pump can

be set to “auto”. It is used if there is a trip of the generator in service,

automatically starting to supply lube oil as the turbine runs down to a stop.

6. Open cooling water valves to oil cooler

and generator air cooler. This will circulate seawater through these coolers.

The oil and air gets hot as the generator loads up.

7. Start the condensate extraction pump;

this uses 3.5kW of our dwindling emergency supply. The pump will circulate the

condenser water via the regulator valve back to the condenser. Once the

condenser starts to fill to the set level, the regulator will redirect the water

to the feed system.

8. Turn gland leak-off 3-way cocks to

engineroom leak-off, and then seal the glands. The glands are at the ends of

the turbine shaft, and if left unsealed, will allow steam to flood out of the

ends of the shaft - not good. They also prevent air being drawn in under the

vacuum at the low-pressure end.

9. Turn on steam supply to the air pump

(“vacuum augmenter” secondary jet). This will start removing non-condensables

out of the condenser and improve the vacuum.

10. Open stop valve slightly to warm

turbine. This will allow steam to flow slowly into the turbine and start to

warm up the blading and casing. This is important in order to allow the turbine

to expand to its working condition. Too fast and the blades will bind on the

stator - not good.

11. When vacuum has reached 20 inches, open

the stop valve until the turbine starts to turn, closing it somewhat

immediately afterwards to prevent the turbine gaining speed too rapidly.

12. Gradually speed up, then keep turbine

running at about half revolutions (2500rev/min) for ten minutes, then bring it

steadily up to full speed in not less than five minutes. At full speed, the

speed governor will come into action and take control of the machine. Open the

stop valve fully. The machine is now whirring away (quite quietly), and we

check round all the gauges to make sure all is OK - oil pressure, steam

pressure and temperature, vacuum (very

important), and all bearing temperatures.

13. Stop the auxiliary motor-driven oil

pump, and switch to ‘Auto’ control so that it starts if we get a turbine trip.

Normally we would test the trip at this stage to make sure the control system

works.

14. Vent the condenser and vacuum pump

circulating water spaces and check condenser water level is being regulated properly.

15. Turn on steam supply to vacuum pump

primary jet. Adjust this to give the best vacuum with lowest possible steam

pressure.

16. The turbine is now running “straight

condensing” in that the steam is passing through the blading and exhausting to

the condenser, where it is condensed into feed water.

17. Shut off the external gland steam

supply and open the valve controlling gland steam leak-off into the turbine to

reduce the leak-off to the engineroom drains.

18. Set the speed at about 5200rev/min to

allow for some speed drop when load is applied. This will give a speed at the

generator end of 530rev/min.

The turbine is now running under the

governor, and we can call the main switchboard for the electrician to apply

electrical load on the board by closing the dynamo circuit breaker. We can send

one of the junior engineers up top to stop the emergency generators and make

sure they are switched to automatic in case we lose power on the main bus.

The engine room is now starting to come

alive, with the hum of the dynamo and the noise of the seawater circulating and

condensate pumps.

We can call the boiler room and let them

know that they can close the superheater starting-valve. There is now enough

power to get as many boilers on line as we require for going to sea but before

we do that, there are some other important things needing our attention in

order to keep things going.

te / ss NORMANDIE, Figure 26 Starboard Inner Turbo-dynamo set - editors collection

Here’s our turbo-dynamo set, running

relatively quietly. The turbine is at the left hand side (forward), with the

generator on the right (aft). The gearbox is shown in the middle. The condenser

and pumps are mounted underneath - the ladder in the foreground goes to the

lower level. If required we now have all we need to start a second or more

dynamos depending on the load. The firemen can now start all the forced draft

and stokehold ventilation fans, change over from electrical heating to steam on

the fuel oil heaters and use the large full power fuel oil pumps. The “cold

start” oil pump and heater can be shut down. The boiler stop valves are opened

as required depending on the steam pressure in the main piping.

5 The Feedwater and Condensate system

This important system covers the closed feed system of a large steam plant. The system and its auxilliaries carry out the following basic operations:

1) To pump water into the boilers to maintain the levels

2) To extract the condensate from the condensers

3) To maintain the level in the condensator

4) To use exhaust steam and hot returns to heat the feedwater so produced

5) To filter any oil/grease out of the water prior to pumping back to the boiler

The feed and condensator system is designed to extract the maximum energy from the steam and return the heated feed water back to the boilers at the maximum design temperature. There is little or no information about NORMANDIE´s feed condensate and drain systems, so we will have to rely on experience to figure things out.

there atre two feed systems on the ship, one for the turbo-dynamo system and one for the main propulsion turbo-alternators. We will cover the dynamo one first otherwise we will run out of water in the boilers, so we need to be quick in continuing our juggling act.

te / ss NORMANDIE, Figure 27 one of the Dynamo Turbo-feed pumps - editors collection

The turbo-feed

pumps “T1” are compact units; in the picture at Figure 26 the steam turbine

is on the left with the multi-stage centrifugal pump on the right (note that a lot of equipment in passenger

ships of the era was British made, as befitted the then premier shipbuilding

nation of the world).

These pumps, along with the larger

propulsion feedwater pumps, are situated at the after end of Boiler Room4, so

we have to duck back through the watertight door at the forward lower level of

the turbo-dynamo room and into the boiler room where we will find two of these

pumps, “T1” on the drawing in Figure 19 and Figure 20. To start this pump we need to drain the steam

lines as usual to avoid damaging the turbine, and line up the exhaust to the LP

and HP feed heaters “X1” and “Y1” above the pumps in order to heat the

returning feedwater to the boilers.

Opening up the control valve to admit steam, the turbine runs up to

speed, exhausting through the heaters to the drains cooler and delivering

feedwater from the feed tanks to the boiler level controllers. By this time the boiler levels will have

dropped somewhat, and our firemen will be relieved to see the water levels

begin to rise. The feed pump will run

just about unattended, as it is fitted with a discharge pressure operated governor: If the feed demand is zero (i.e. all the

boiler level controllers are closed) then the discharge pressure will rise and

act on the governor to reduce the speed of the turbine (in practice once at

least one turbo-dynamo is running, there will always be some demand on the pump

in a closed-feed system), and conversely as the boiler levels drop, the feed

controllers will open, reducing the discharge head and speeding up the turbine

accordingly. Inherent stability of

operation is a feature of the Weir (and its close cousin, Coffin) feed

pumps. The pumps can deliver 75m3/hr of

feedwater to the boilers at 36.5kg/cm2 pressure (to overcome the boiler

pressure of 28kg/cm2).

From the boilers the steam passes to the

turbo dynamos. Steam from the dynamo exhausts

that has condensed into the hotwells under the condensers is returned to the

feed system using the sets of condensate

pumps “23” located at the lower platform level (Figure 27).

te / ss NORMANDIE, Figure 28 Longitudinal view of turbine room - copy from The Shipbuilder

These electrically driven pumps draw from

the bottom of the condenser well and deliver the condensate either back to the

condenser to maintain the level via the level

controller, or to the feed tank

“25” in Figure 27. They are similar in

type to the main condensate pumps, though smaller in size.

The turbo-dynamo

feed pumps “T1” – two sets - located in Boiler Room 4 (Figure 19 and Figure

20) draw the water from the feed tanks and discharge it through the feed

heaters, which use various drains, bled steam from the turbines and exhaust

steam from auxiliary systems to heat the feed water. The first stage (LP) uses auxiliary exhaust

steam supplemented by bled steam from the turbine at 0.5kg/cm2, whilst the

second stage (HP) utilises bled steam only at a pressure of 2.5kg/cm2. The feed – at high pressure – passes through

the tube nest, whilst the heating steam passes through the shell.

From the high pressure feed heaters “Y1” the water passes into the boiler

feed main, from where it is fed to the boilers by automatic feed regulators

working off the boiler level. The

turbo-dynamo feed pumps run in conjunction with the main feed pumps for the

propulsion feed system mentioned later.

The exhausts from the feed heaters, after transferring their heat to the

feed, pass via a drains cooler “Z1”

and thence back to the drains collection system.

We now have a stable system running, with

the steam from the boilers supplying the turbo-dynamos, the returns from the

condenser passing via the turbine driven feed pumps, through the LP and HP feed

heaters and the back to the boilers. Our

juggling act has come to fruition without dropping any balls… We can now turn our attention to the main

propulsion system, and get it ready for sea service. Things are starting to hum along quite

nicely.

6 Main propulsion turbo-alternators

We are now up and running with all systems that we need to start the main propulsion. there is no physical link between the power to drive the ship (the turbo-alternators) and the propulsion motors that actually drive the shafts, other electrical cabling. This is novel in that the two systems may be placed conveniently without any need for shafting connections as in direct drive or geared turbine propulsion units

To dive the motors we first have to start the turbo-alternators in order to supply the power for the motors. The main turbines - of which there are four - are very similar to the dynamo sets that we started, so the two systems complement each other.

te / ss NORMANDIE, Figure 30 Lower platform level - copy from The Shipbuilder

First we will get a main seawater

circulating pump going for which we need to open the seawater induction and

overboard valves.

Ref

|

Qty

|

Designation

|

1

|

4

|

Turbo-alternator hp turbine

|

2

|

4

|

Turbo-alternator lp turbine

|

3

|

4

|

Main Propulsion Alternator

|

4

|

4

|

Condensers

|

5

|

8

|

Main Sea Circulating pumps

|

6

|

6

|

Condensate pumps

|

7

|

4

|

Vacuum augmenter

|

8

|

4

|

Hotwell tanks

|

9

|

4

|

Feed regulators

|

11

|

4

|

Sea induction valves

|

12

|

8

|

Seawater overboard discharge valves

|

13

|

6

|

Oil Pumps

|

14

|

4

|

Oil Coolers

|

15

|

2

|

Oil Sump Tanks

|

16

|

2

|

Cooling Pumps for oil coolers

|

17

|

2

|

Cooling Pumps for alternator air coolers

|

18

|

2

|

Bilge injections for alternator

compartment

|

19

|

1

|

Bilge injection for motor compartment

|

These valves are “11” and “12” on the diagram,

they are large, and will take some swinging, so we could use a hand. Each

condenser has two pumps, each of 7000m3/hr delivery - quite a lot - so

presumably two are fitted in order to reduce the size of a single unit of

14,000m3/hr, which even today would be too big to fit in an average engineroom.

Even 7000m3/hr requires a lot of space, as shown in the photograph below –

Once the valves are opened, we will go to

the pump starter and start both pumps for each turbine set. At 7000m3/hr and

9.5m head, they consume around 232kW each, but we have plenty of electricity

available and can start other dynamos if we require them. We check the seawater

pressure before and after the condenser to make sure there is no blockage in

the tubes.

This turbine is slightly different in that

it is a two-stage unit, with an HP and LP set of turbine blades to extract the

maximum energy from the steam. The set is very large, as are the auxiliaries

like the condenser and pumps, so to the uninitiated it’s all a bit intimidating

especially with around four dynamos already running with their attendant pumps,

plus the ever-present ventilation noise.

Here’s a sectional view of the propulsion

turbo-alternator

te / ss NORMANDIE, Figure 32 One of 4 Main Seawater Circulating Pumps - copy from The Shipbuilder

On the right are shown the turbine glands

and bearings at the free end, similar to the turbo-dynamos. Above is the large

control valve that operates the turbine. Carrying on to the left can be seen

the turbine cylinder in which there are sets of blading, starting with two sets

of impulse blading (which use the velocity of the steam to do work on the

blades), followed by the rows of reaction blading through which the steam

expands and turns the blades. On exiting from the reaction HP blading, the

steam passes through the large “suitcase handle” bends and into two sets of LP

blading, one fore and one aft, thereby extracting more energy from the steam,

finally exhausting to the condenser through the large opening below the

blading. The condenser is mounted underneath this opening, attached via a

bellows piece to allow for expansion, contraction and vibration between the

units. These are large machines, as shown in the photos below. Note the

“suitcase handle” bends –

Now that we have all the lights on in the

turbine room, everything is bright and pleasant - most unlike other ships of

the era that were gloomy places in which to work. In both pictures you can see

the “suitcase handle” bends between the HP and LP turbine wheels, and in the

bottom picture, the electrical switchboard - this is a starboard outer unit,

and the more observant amongst you will notice that the ladders are not in the

same direction as the plan! Alongside is one of the many switchboards for the

machinery; there’s another one next to the port outboard turbine set.

te / ss NORMANDIE, Figure 31 Transverse section at Fr 119 looking Forward - copy The Shipbuilder

te / ss NORMANDIE, Figure 37 Lower platform level - copy The Shipbuilder

te / ss NORMANDIE, Figure 37 Lower platform level - copy The Shipbuilder

These are really huge pieces of

engineering, and we are going to start them up in readiness for sailing,

starting with the port outboard set, shown at the top of Figure 32.

1.

|

Again we check that there is a level of

water in the condenser “4” of the first unit - there is a gauge on the side

for this.

|

2.

|

We open the valves on the suction and

discharge side of the condensate pumps “6” and start them up. The water is

pumped from the bottom of the condenser and back in at the top. As the level

is quite low, the pump can be left to its own devices, circulating the

condenser. Once the level starts to rise, the automatic regulator will start

to divide the flow between the condenser and the feed tanks.

|

3.

|

As there are one or more turbo-dynamos

running, we know that the steam is dry and up to temperature in the main

steam lines, ready for us to start warming through the propulsion turbines.

4. Re-set the emergency governor. This

will have been tripped to stop the turbine when it was last used.

|

5.

|

Open all drains (main steam stop valve, turbine cylinder, main steam strainer).

This will ensure there is no water collected in the cold piping as it comes

into contact with the steam from the main lines. Make sure the drains are

clear and steam is issuing out of them.

|

6.

|

Check that the seawater supply to the

condenser is still satisfactory.

|

7.

|

Check that the motor-driven oil pump

starter switch is in “on” position. Start the pumps “13” (there are 6 of

these, two are redundant units) and allow the oil to circulate through the

turbine, gearbox and generator bearings. Once the turbine is up to speed, the

engine-driven LO pump will supply the pressure, and this pump can be set to

“auto”. It is used if there is a trip of the generator in service,

automatically starting to supply lube oil as the turbine runs down to a stop.

There are sight glasses on the bearings where we can see the oil swirling

round them.

|

8.

|

Open cooling seawater valves to the oil

coolers “14” and start the oil cooler seawater cooling pump “16”. The circuit

has a thermostatic valve to maintain the oil temperature as the turbine warms

up.

|

9.

|

Open the valves on the cooling seawater

pump for the alternator air coolers. This will circulate seawater through the

cooling coils in the alternator. Again it has a thermostatic valve to maintain

the temperature of the armature windings.

|

10.

|

Turn gland leak-off 3-way cocks to

engineroom leak-off, and then seal the glands by admitting steam. The glands

are at the ends of the turbine shaft, and if left unsealed, will allow steam

to flood out of the ends of the shaft - not good. They also prevent air being

drawn in under vacuum when the turbine is stopped. A small amount of steam

leakage at this stage will prove that there is no chance of air being drawn

in; we will adjust the gland steam pressure later under running conditions.

|

11.

|

Turn on steam supply to the air ejector

(“vacuum augmenter”) “7” (next to the seawater pumps) secondary jet. This

will start removing non-condensables out of the condenser and improve the

vacuum.

|

12.

|

Turn the engine on the turning gear. This

machine engages with a gear on the turbine shaft, and slowly turns the

turbine to avoid “rotor sag”. It is useful when we are warming through, but

there is an interlock that stops us from allowing the steam control valve to

open. Withdraw the turning gear once the engine is warmed through, otherwise

the control valve won’t open.

|

13.

|

Open the main stop valve slightly to warm

the turbine. This will allow steam to flow slowly into the turbine and start

to warm up the blading and casing. This is important in order to allow the

turbine to expand to its working condition. Too fast and the blades will bind

on the stator - not good. The steam will condense as it passes through the hp

and lp turbines, and run down to the condenser. It will take some time to

warm through such a large machine, and experience tells us when we can go on

to the next step.

|

14.

|

When vacuum has reached 20 inches, we

open the stop valve until the turbine starts to turn, closing it somewhat

immediately afterwards to prevent the turbine gaining speed too rapidly due

to the large rotating masses.

|

15.

|

Gradually speed up, and then keep the

turbine running at about 10% full revolutions (250rev/min) for ten minutes,

then bring it steadily up to 20% of full speed (500rev/min) in not less than

fifteen minutes.

|

16.

|

There are two governors on these

machines, (a) an oil pressure governor, which controls the speed between 7%

and 20%, and (b) a centrifugal governor to control between 20% and 100%. This

means that the speed of the propulsion motors, driven by these alternators,

can be controlled asynchronously by varying the speed of the alternator. We

will discuss this once we are in the propulsion motor room

|

17.

|

At 20% speed the centrifugal governor

will now come into action and take control of the machine from the oil

pressure governor.

|

18.

|

We can now open the stop valve fully, as

the governor will control the engine speed. The machine is now rumbling away

(quite quietly), and we check round all the gauges to make sure all is OK -

oil pressure, hp steam pressure (23.5kg/cm2) and temperature (around 325C),

vacuum (very important), and

all bearing and alternator temperatures. We need to take our time about this,

making absolutely sure everything is functioning correctly.

|

19.

|

As the turbine-driven oil pump is now

supplying the system, we can stop the auxiliary motor-driven oil pump and

switch it to ‘Auto’ control, so that it starts if we get a turbine trip.

Normally we would test the trips at this stage to make sure the control

system works, so will assume that we have done this.

|

20.

|

Vent the condenser of air by opening the

vent cocks at the top, and vent the vacuum pump circulating water spaces.

Check again that the condenser water level is being regulated properly. We

will shortly be starting up the feed heating system instead of returning the

water to the feed tanks when the proper condenser level is reached.

|

21.

|

Turn on steam supply to vacuum ejector

primary jet. Adjust this to give the best vacuum with lowest possible steam

pressure.

|

22.

|

The turbine is now running “straight

condensing” in that the steam is passing through the blading and exhausting

to the condenser, where it is condensed into feed water.

|

23.

|

Shut off the external gland steam supply