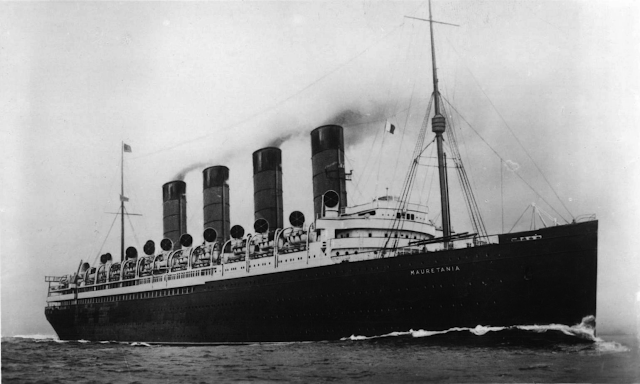

rms MAURETANIA,

1907, Cold Starting

CUNARD LINE

Ltd., Builders: SWAN, HUNTER & WIGHAM RICHARDSON. Newcastle on Tyne

by Stephen Carey, engineer, editing by Earl of Cruise

rms MAURETANIA © Stephen Carey

1 Overview of machinery spaces

1.1 Boiler rooms

MAURETANIA is (or was) a quadruple

screw Cunard liner fitted with 2 single-ended and 23 double-ended boilers,

operating at 195lb/in2. These boilers

are arranged six in 3 boiler rooms (4,3

& 2; note that Cunard numbers forward to aft compared to White Star

which numbers aft to forward), and five in No1 Boiler Room (the foremost one)

where the fine lines of the ship only allow 2 abreast at the forward end of

this boiler room.

No1 Boiler Room also houses the two

single ended boilers used for hotel services and auxiliary supplies in

port. The double-ended boilers are fired

for transatlantic passages up to full speed and primarily used for main

propulsion.

Combustion air for the boilers is

provided by forced draught fans, so for cold starting these have to be run up on

the shore electric supply before firing the boilers.

1.2 Coal bunkers

Coal bunkers are provided either

side of the stokehold furnaces in each boiler room to enable a ready supply of

coal for the trimmers and firemen to stoke the boilers. These bunkers form the double side of the

ship through all the boiler rooms (unlike Titanic which has transverse bunkers

either side of the transverse watertight bulkheads).

Ash chutes are provided to

discharge ash from the furnace bottoms overboard at regular intervals to keep

the stokehold clear of ash whilst at sea.

In port ash hoists are used to dispose of the ash to shore facilities.

The main steam pipes run the

length of the boiler rooms to the bulkhead stops in the centre engineroom for

distribution to the engines and auxiliaries.

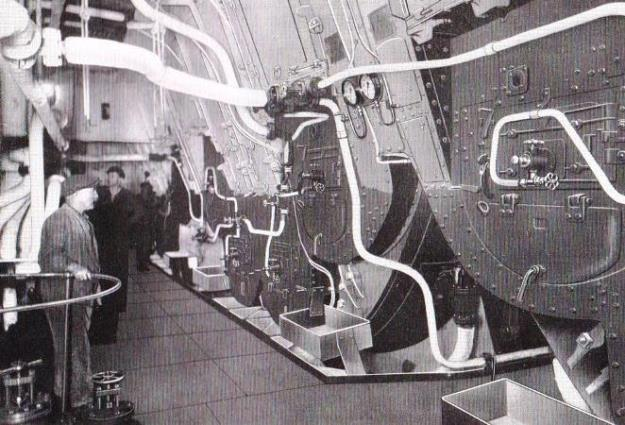

Figure 1

Mauretania's stokehold prior to conversion

1.3 Propulsion engines

There are two high-pressure

turbines situated in the wing watertight turbine rooms, aft of Boiler Room No4. Steam from the main steam piping is admitted

to the high-pressure turbines, which then exhaust into the ahead low-pressure

turbines situated in the centre engineroom.

Exhaust steam from the low-pressure

turbine is directed to the vacuum condensers, situated in a further watertight

compartment aft of the turbine room, where it is condensed into feed water and

pumped back into the boilers.

Manoeuvring from ahead to astern

is carried out on the lp ahead and astern turbines, the hp turbines playing no

part in the astern operations. Steam is

directed either ahead or astern by means of a large manoeuvring valve driven by

a steam driven gear. The main exhaust

sluice valve for directing steam from the hp turbine to the condensers direct

(i.e. bypassing the lp turbines) is electrically driven. This bypassing is only used in an emergency,

as it is extremely inefficient to exhaust the hp turbines straight into the

condensers.

Regulating valves driven by worm

and quadrant gear via spindles operated from the starting and manoeuvring

platform, admit steam to the engines as required by the telegraph orders.

2 Electrical power generation

2.1 Main generating sets

The vessel is fitted with 4 375kW

110Vdc main turbo-generators driven by Parsons steam turbine prime movers. These sets are situated two to a watertight room

aft of the condenser watertight room, separated by a centreline watertight

bulkhead, ensuring maximum redundancy from damage. As the vessel is not fitted with either

auxiliary or emergency generators, it is assumed that the watertight

arrangements of these compartments would ensure the reliability of the

electrical generating supply.

Steam at a pressure of 195lb/in2

is fed to the turbines and exhaust steam is directed in port or at start up to

the auxiliary condensers. At sea the

exhaust steam is directed to the surface and/or direct contact feed heaters to

extract the remaining energy from the exhaust steam and deliver it to the feed

heating system. This configuration gives

a total installed power of 1.5MWdc, with three sets covering the full steaming

load and one in stand-by.

2.2 Auxiliary/emergency generating sets

There are no auxiliary or

emergency generating sets on MAURETANIA.

Figure 2

Generator room and switchboard

3 Firing up the boilers

The engineers start the required

forced draught fans on the shore power supply.

Assuming that for a main generator to run we need at least all the fires

in one boiler room lit, one FD fan is started to supply the furnaces in one of

the main boiler rooms. The firemen are

set to work in this Boiler Room to lay fires in all required furnaces. Once lit, the boiler draft is adjusted by

dampers and the fires start to heat the water in the fire-tube boilers. Water-tube boilers are much more efficient

and faster starting than fire-tube, but hadn’t been invented at this time. It would take around 12 hours to raise steam

to manoeuvring pressure.

It’s now 12 hours on, and we have

around 190lb/in2 at the main stops to the main steam lines to the enginerooms. The main stop valves of the boilers are open

to the main steam pipe during firing in order to bring up the piping

temperature to that of the first boilers lit, such that the piping and valve

drains clear the lines of condensate, which can damage reciprocating and

turbine machinery. The remaining boilers

are banked with main stops closed until main power is available and more steam

is needed.

4 Starting the generators

4.1 Auxiliary seawater pumps and condensers

In order to start a turbo-generator,

the exhaust steam from the engines is directed to an auxiliary condenser, of

which there are two; one in each of the watertight auxiliary condenser rooms

situated either side of the centre turbine room. The seawater passing through this condenser

condenses the exhaust steam into water, thereby dropping its pressure. Without this the engine would trip on high

exhaust backpressure, as the exhaust steam has nowhere to go. In addition the condenser is supplied by an

auxiliary air pump (or vacuum pump) to increase the vacuum by removing

non-condensables such as air and CO2 in order to drop the exhaust steam

pressure further.

The auxiliary seawater pumps are

steam driven and situated in the same room as the auxiliary condensers. The sea suction and discharge to condenser

valves are opened prior to starting.

With the pump cylinder drains

open, steam is admitted to the pump, which gains speed and starts to circulate

seawater through the auxiliary condenser to overboard. In the same way the auxiliary air pump is

started in order to draw a vacuum. Once

these two pumps are up to speed we are ready to start the main generators.

4.2 Starting the main generators

As we will soon be consuming

steam, we will also need to be able to start a main feed pump to supply the

boilers with feed water as required – see later.

The generator bearings are forced

lube type, so first we start a LO pump (again steam driven, as are nearly all

the engineroom auxiliaries) in the same way as the seawater pump above. The LO pump supplies oil for the bearings as

well as control oil for the generator throttle valve. In this way, a failure in LO pressure will

automatically trip the generator to avoid damage to the bearings.

After warming through the generator

steam lines and opening the turbine exhaust to the auxiliary condenser, the

first and subsequent generators are warmed through and run up to a speed of 1200rev/min.

On the main switchboard (of which

there are two, joined by a bus-tie breaker), the breaker is closed for the

generator in question and the shunt field regulator adjusted to give mains 110Vdc

voltage. There is no need to synchronise

dc machinery, unlike alternating current machines. Once the generator has settled down on the

board, the shore breaker is opened to avoid back-feeding the shore supply as

the main generator loads up.

We can now put the other

generators on the board as required. We

are up and running on main power and can connect other feeders via the main

switchboard distribution as required.

As you can see, this is quite a

long job compared to a modern diesel powered ship (though steamships still take

some time). A blackout on a modern

motorship can be restored within a few minutes, whereas a steamship takes much

longer.

5 Starting main engines

We now have power for all the

forced draft fans required to fire all the boilers necessary for starting the

main engines and getting the enginerooms ready for sea.

First we have to get the propulsion

exhaust steam system arranged in a similar way to that of the generators but,

in the case of the main engines, the auxiliary condenser is nowhere near big

enough to handle the exhaust from the propulsion engines.

For this we need to draw a vacuum

on the main condensers, of which there are two, one either side of the watertight

condenser room aft of the low-pressure turbine room.

5.1 Main seawater pumps

As with the auxiliary condenser,

we need seawater to condense the steam and drop its pressure to avoid exhaust backpressure

on the engines. These are pretty huge

and are driven by compound steam engines.

There are two pumps per condenser (total of four) arranged adjacent to

the condensers in the watertight main seawater circulating pump room aft of the

condenser room.

The main sea induction valves and

overboards on the ship’s side are opened for each pump and, as with all steam

engines, the main seawater pump engines are warmed through with the drains

open, then slowly started up until they are at full revs. Once the pumps are running, seawater passes

through the condensers and discharges overboard – that’s the large overboard discharge

that can be seen on any steamship up to the present day.

5.2 Main dry-air pumps and wet-air pumps

The air pumps (called vacuum

pumps these days) evacuate air and water vapour from the condensers and draw a

vacuum in so doing. This improves the

exhaust flow from the engines and also extracts the maximum energy from the

steam. They are situated in the main

circ room inboard of the main circ pumps and are of course steam driven. They are started in the usual way, and left

to draw a vacuum on the condensers, usually around 28.5in with an atmospheric

pressure of 30in. Water from the wet-air

pumps is returned to the feed tank under the condensers, as is air from the dry-air

pumps.

5.3 Main generators

Now that the steam and feed

system is up and running, we can extract the energy from the main generator

exhaust by redirecting it from the auxiliary condenser to the contact or direct

feed heater, through which the condensate from the feed tank passes via the

hotwell pumps (see later) to mix with the generator exhaust steam. This imparts heat to the feed water to avoid

wasting the energy from the generator exhaust.

5.4 Main engines

By this time the engineers (we

assume we are not doing this on our own) will have engaged the electric turning

gear motors on all four shafts, as well as starting the turbine forced lube oil

pumps (steam driven). The engines are

kept turning until required for use, whence the gear is withdrawn to avoid

damage to it in the event of starting a turbine with it engaged. Gland steam is assumed to have been fitted

(no mention in the Engineer & Shipbuilder reprint I have) and will be

started up to extract leakage steam from the turbine shaft glands, and condense

it back to the hotwell drains.

The hp turbines are kept warmed

through ready for working up to speed on passage, with manoeuvring steam admitted

to the lp turbines with the drains full open and the exhausts open to the

condensers. At first the main steam

valves are cracked open until everything is warmed through, whence they can be

fully opened.

Once the turbine drains are

emitting steam, we can call the bridge and ask if the propellers are clear for

a slow turn ahead and astern. Once this

is given, the manoeuvring valve is set to ahead position (which isolates the

astern lp turbine) and the main steam regulating control valve cracked open at the

starting platform at the forward end of the lp turbine room. The engine will start to turn ahead at low

revs. After a few turns of the shafts ahead

the regulating valve is closed and the manoeuvring valve set to the astern

position (which isolates the ahead lp turbine).

Again the regulating valve is cracked open and the astern turbine turned

for a few revs at low speed.

We are about ready to go, and

test the communications between the engineroom, boiler rooms and bridge so that

we are ready for sea service. Around the

same time an engineer is dispatched to the steering engine room to warm through

the steering engines and test the rudder from midships to 30 degrees port, back

to 30 degrees starboard then returning to midships.

Figure 3

Mauretania starting platform

5.5 The feed system

Steam from the condensers that

has condensed into the hotwells under the condensers is returned to the boilers

via two feed heaters using the sets of hotwell pumps located under the main

condensers. These pumps deliver the

condensate to the surface feed heaters

located in the auxiliary condenser rooms.

These heaters are fed with exhaust steam from the auxiliaries (the pumps

mentioned above, such as seawater, air pumps, lube oil pumps etc.) and this steam

heats the feedwater passing through the shell and tube heating elements.

From the outlet of the surface

heaters the feed water is passed to the 2nd of the two feed heaters,

which is a direct/contact heater

where the water comes directly in contact with exhaust steam from the main

generating sets. These heaters are situated

high in the engineroom above the astern turbines and act as a deaerator once

the air vent at the top of the heater is opened up to the main condenser to

extract undesirable gases (CO2 and O2), which can cause corrosion problems in

the boilers. In this heater the generator

exhaust steam condenses in contact with the boiler feed water stream from the

hotwell pumps and is then extracted under gravity by the main feed pumps and

sent to the boiler distribution mains as required. Mauretania did not have automatically

operating feed control valves, so this was a manual operation. Its height ensures that there is sufficient positive

suction head for the main feed pumps that feed the boilers. All is now ready to go, with the stokers

bending their backs to raise steam on all the boilers required for leaving

port.

6 Getting under way

In response to the bridge signals

on the engineroom telegraphs, the lp turbines are manoeuvred accordingly as above

and the ship departs her berth and heads for the open sea.

7 High-pressure turbines

Once the ship is up to full

ahead, and prior to full away, the two high-pressure turbines (which have been

kept warmed through with their exhausts directed to the two ahead lp turbine

inlets) are started via their regulating valves and brought up to speed. The wing turbines (and shafts) are now

driving ahead and adding to the thrust of the lp turbines on the inner

shafts. The steam is now passing from

the boilers to the main steam lines, through the hp turbines, into the lp

turbines and exhausting to the condensers, from where it is returned to the

boilers as above in a closed feed cycle.

Full power can now be worked up once full-away is rung on the

telegraphs.

We’re done, we’ve been down below

on a coal-burner for over 12 hours, and it’s time to go to bed before having to

get up again and win/keep the Blue Riband of the Atlantic.

Figure 4

View between the lp turbines and starting platform

8 Coal-firing vs oil-firing

Coal-firing was a dirty, messy,

labour-intensive way to feed a furnace.

As well as bunkering and firing the boilers, disposal of the ash was an

additional burden on the stokehold staff.

“Coaling ship” was an “all hands” task where everyone turned to so fill

the coal bunkers via coaling ports in the side of the ship.

Oil-burning on the other hand is

far less labour-intensive, with the bunkering taking place via a hose from a

bunker barge in to the same bunkers as the coal was previously.

A coal-fired ship needed some 250

stokehold staff to fire and tend the boilers, whereas ships like Mauretania

when converted to oil-firing only needed some 60-odd stokers.

Figure 5

Disposing of ash from a furnace

Figure 6 Filthy conditions in a coal-fired stokehold

Figure 7 MAURETANIA stokehold after conversion

Figure 8

MAURETANIA boilers after conversion

From the pictures above, compared

to the filthy conditions in a coal-fired ship, can be seen the huge improvement

in working conditions once the stokehold had been converted to oil firing.

In addition, firing on oil was

far more efficient, and the power output of MAURETANIA improved substantially

after conversion, as did the overall Specific Fuel Consumption. As there was no requirement to discharge ash

overboard, the ship was much cleaner and – even though the environment was not

much considered in those days – oil firing opened up the world shipping fleets

to better environmental conditions. The

volume of smoke seen issuing from the funnels of these large passenger ships

also reduced dramatically; an oil-fired boiler is designed to run cleanly, with

no smoke other than a haze at the funnel tops, whereas it was difficult to

avoid smoke – especially whilst manoeuvring – from over 20 boilers fired on

coal. The coal fires are slow to react

to changes in steam demand and draught requirements, whereas oil-firing can

react immediately.

One procedure that didn’t really

improve was the length of time taken to raise steam in fire-tube boilers, and

it was some years before the next major trans-Atlantic steamship was built

using water-tube boilers. This was the

Empress of Britain, which will be discussed in a further document on starting

these large liners from cold.

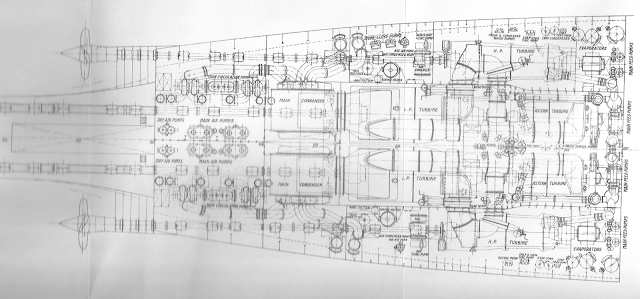

Figure 9 Plan of boiler rooms up to the

ER bulkhead

9 Profile and plan of boiler rooms

On the view

in Figure 5 can be seen the extent of boiler rooms

2,3 and 4, with a hint of Boiler Room 1 at the fore ends. The boilers are installed 6 to a room.

10 Uptakes and ash ejectors

The uptakes

can clearly be seen, illustrating that all four funnels on this vessel served

the boilers (unlike the TITANIC, whose aft funnel was a ventilation shaft.

Zooming in

on the drawing shows the ash ejectors in boiler rooms 2&4, and the ash

ejector pump is shown in boiler room 2.

11 Auxiliary feed pumps

There is an

auxiliary feed pump either side of the watertight bulkhead between numbers 2

& 3 boiler rooms. No1 and No4 boiler

rooms also have an auxiliary feed pump and ash ejector.

12 Main steam lines, RD fans and escape ladders

On

the profile view, note the main steam lines running the length of the ship

above the boilers, the forced draft fans mounted on the Orlop Deck. Also the vertical ladders the same as the

TITANIC where they stokers can get out of the stokehold if the watertight doors

are closed.

Figure 10 Plan of machinery spaces

Figure 11 Elevation of machinery spaces

13 Plan and elevation of machinery rooms

The views in

Figure 5 and Figure 7 show the forward engineroom bulkhead on which

are the bulkhead stops for the two main steam lines exiting from No4 boiler

room. The bulkhead stops are actuated by

Brown’s steam engines as they are too large to manually operate. The engine overspeed governor can act on

these valves and shut off the steam in the event of overspeed.

The turbines

and equipment are mirrored for each pair of shafts. For the notes below we will consider the port

side pair of shafts to avoid repetition.

14 Steam lines

The steam,

after passing though a strainer to remove particles, is directed either to the

hp turbine via the pipe passing through the watertight longitudinal bulkhead,

or aft to the lp turbines via the large double manoeuvring valve shown at Fr 94. The starting platform from where the engines

are driven ahead and astern is located at the forward end of the astern lp

turbines and can be seen around Fr 104.

The starting wheels comprise a large outer wheel for the bulkhead stops,

and a smaller inner wheel for the manoeuvring valve. The levers for controlling the turbine drains

and sluice valves are close by.

15 Turbine isolation

Taking the

port hp turbine as an example, there are two exhaust pipes exiting from the

turbine casing, both of which have large sluice valves installed. The after larger one (75”) directs hp exhaust

steam into the inlet of the lp turbine, which is the normal mode at sea. The other smaller (60”) sluice valve directs

the exhaust straight to the condenser (in the event that the lp set is out of

service) and is therefore normally closed.

Whilst manoeuvring, both sluice valves are kept shut to avoid steam back

flowing from the lp turbines into the idle hp turbines.

The exhaust

from the lp turbines to the condensers is the large length of piping shown at

the aft end of the ahead lp turbine, which passes through two watertight

bulkheads and into the main condenser.

16 Main manouvering valves

Around Fr 93

and in line with the steam lines to the lp turbines can be seen the double

outline of the manoeuvring valve that directs steam either into the ahead lp

turbine (the larger pipe) or the astern turbine (the smaller pipe).

17 Feed water pumps

Along the

forward bulkhead in both hp and lp engine rooms are arranged the main feedwater

pumps. These pumps draw from the

direct/contact feed heater mounted on the flat above the turbines

18 Auxiliary equipment

A set of

evaporator machinery for producing fresh water is installed in each hp turbine

room, while aft of these are the fresh and condensed water pumps in the port

room, and refrigeration machinery in the starboard hp turbine room. Space is therefore limited in both these

rooms.

In the lp

room are fitted the the hotwell, bilge, oil, water service, fire and sanitary

pumps.

In the

Auxiliary condenser rooms can be seen the condensers themselves, the condenser

seawater pumps and air pumps, the main and auxiliary feedwater filters and the

surface feed heaters. The Stone-Lloyd

pumps shown outboard in the port room are for operating the watertight doors.

19 Main condenser room

In the main

condenser room are installed the main condensers. Note that there is no centreline bulkhead in

this room. Mounted under the condensers

are the hotwells for collecting the condensed steam, and the hotwell pumps

which pump the condensate into the feed system.

20 Auxiliary machine rooms

Aft of the

condenser room, the next watertight compartment contains the two large main

condenser seawater-circulating pumps, the main wet-air pumps and the dry-air

pumps for creating the vacuum on the condensers. The dry-air pumps are mounted one set above

the other.

Above the

auxiliary machinery room is situated the turbo-generator room and its attendant

main switchboard.

21 Shafting and propellers

From the

thrust bearings mounted at the aft end of the lp turbines (the engines which

are coupled to the centre shafts) the two propulsion shafts are arranged in the

shaft tunnels and exit the ship via the stern tubes. There are several intermediate bearings

(Plummer Blocks) along the length of the shafting which are splash lubricated.

Written by Stephen Carey

Comments

Post a Comment