rms EMPRESS OF BRITAIN, 1930, Cold Starting

Canadian Pacific Steamships Ltd., Builders: John Brown, Clydebank

Canadian Pacific Steamships Ltd., Builders: John Brown, Clydebank

rms EMPRESS OF BRITAIN - own collection

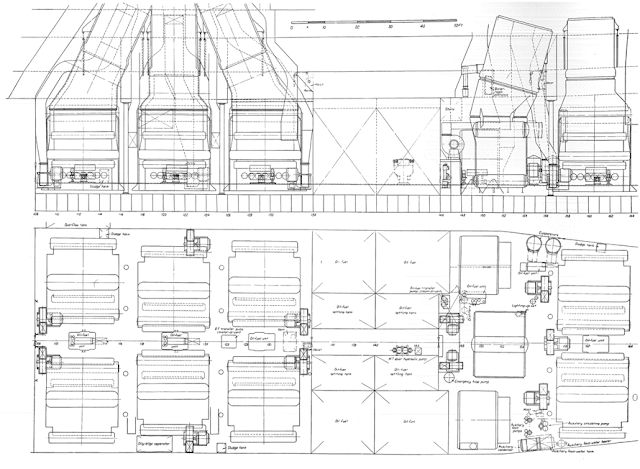

1 Overview of the machinery spaces

1.1 Boiler rooms

The ship is (or was) a quadruple screw Canadian

Pacific liner fitted with two Scotch fire-tube boilers at 200lb/in2,

one Johnson water-tube boiler and eight Yarrow 5-drum water-tube boilers,

operating at 425lb/in2, 725°F

superheated. In SI units this converts

to 13.8bar saturated (198°C) for the

Scotch boilers, and 29bar, 385°C

superheated. At 29bar the saturated

temperature is 234°C, so the

boilers operate at 151°C superheat.

The boilers are arranged in 2 boiler rooms,

one forward and one aft, separated by oil fuel tanks.

In the forward boiler room are the 2 Scotch

boilers, the Johnson boiler and two Yarrow boilers. In the aft boiler room are the remaining 6

Yarrow boilers. A profile and plan of

the boiler rooms is shown at Figure 15.

1.2 Oil bunkers

The boiler oil fuel bunkers are arranged

between the forward and after boiler rooms, and comprise 4 storage and 4

settling tanks. The latter separate oil

from water and other solids by gravity, and are regularly sludged to remove the

water prior to it being pumped to the boiler oil-firing apparatus. The oil-firing or burner pumps are arranged

between each pair of Yarrow boilers.

The 4 main steam pipes run the length of the

boiler rooms to the bulkhead stops in the centre engineroom for distribution to

the engines and auxiliaries.

1.3 Diesel fuel bunkers

Diesel fuel for the generators is stored in double

bottom tanks under the generator room.

The fuel from these tanks is drawn via the diesel transfer pumps located

midships and discharged into service tanks on the forward bulkhead of the

diesel generator room (aft of the after boiler room). There does not seem to be a diesel purifier

on the ship drawings, so presumably the reasonably clean bunker fuel was passed

to settling tanks to drain off the water – probably the two tanks shown on the

port outboard side – before being pumped to the service tanks. From there filtration would clean the fuel of

any other solid impurities prior to injection into the cylinders.

1.4 Propulsion engines

The propulsion system differs from the older

vessels in this series as the turbines are arranged for triple expansion in

each turbine set. The turbine sets each

comprise an hp, lp and ip turbine working each shaft. Astern turbines are fitted on the inner two

shafts only, the outer shafts being ahead running only. The reason for this is that the 2/3 of the

vessel’s propulsive power is provided by the inner sets of turbines working

together, with 1/3 power delivered by the two wing turbine sets operating

together.

The vessel is innovative in that she is

designed for transatlantic service on 4 shafts at maximum power in the winter

months, and for summer cruising on the inner turbine sets, with the propellers

removed from the outboard shafts. The

cruising speed of 18knots is achieved at about half the consumption of all 4

shafts running together, a very economical design.

The ship has a very comprehensive redundant

system for running the turbines together or in isolation, but we will explain

the normal triple-expansion arrangement later.

1.5 Main steam piping (see Figure 1)

Each bank of three boilers in the after

boiler room supply a steam line (2 lines in all) and two steam lines from the

forward boiler room carrying the combined output of the three forward boilers.

Steam from these four main steam pipes passes

through the diesel generator room and enters the forward engineroom via

bulkhead stop valves operated by Brown’s engines and governors from the

turbines, which shut off the steam supply in the event of turbine overspeed.

From the stop valves, the outer steam pipes

pass to the two turbine sets in the forward engineroom, the inner two pipes

pass through the forward engineroom to the bulkhead stops on the after

engineroom bulkhead. From the stop

valves on both the forward and after engineroom bulkheads, the steam passes to

the turbine manoeuvring valves in each section.

The steam passes through each turbine stage

and finally exits to the condensers from the lp turbine exhausts.

This exhaust steam from the low-pressure

turbines is directed to the four vacuum condensers, situated under each of the

four turbine sets, where it is condensed into feed water and pumped back into

the boilers.

Manoeuvring from ahead to astern is carried

out solely using the forward engineroom ahead and astern turbines, with the

wing turbines – which do not have astern turbines - used for working up to full

speed on North Atlantic service. The

turbines may be isolated in case of breakdown.

For cruising operations in the summer months,

the outboard engines are not used, the shafts having their propellers removed

to reduce drag. This results in a

significant reduction in fuel consumption at the expense of unnecessary speed,

the latter only being required on the North Atlantic run.

Regulating valves, driven by worm and

quadrant gear via spindles operated from the starting and manoeuvring platform,

admit steam to the engines as required by the telegraph orders.

Figure 1 rms EMPRESS OF BRITAIN Plan of steam piping in enginerooms

1.6 Gearboxes

Unlike the previous two turbine-driven ships,

which were direct drive owing to the slower speed of the turbines with

low-pressure saturated steam, this vessel has single reduction gearing via four

gearboxes, one for each shaft, to cope with the speed of the turbines under

superheated high pressure steam conditions.

1.7 Electrical power generation

i Emergency generating sets

The vessel is fitted with two emergency diesel

generators of 75kW each for emergency lighting, wireless telegraphy as well as

some power circuits. These machines

could be used to cold start, providing the emergency switchboard has a

connection for the FD fans, but with main diesel generators available, this is

unlikely.

The generators, when running under loss of

main power, have a charging capability for the main and ‘panic’ battery banks.

The generators are electric start, so the

engineers would start these machines and put them on the board, at the same

time opening the shore power breaker.

Once the engines are started and put on the

board, the various circuits required for starting the main generators are

energised, up to the capacity of the emergency switchboard.

Figure 2 rms EMPRESS OF BRITAIN Emergency generator set

ii Emergency switchboard

Attached to this board are the emergency distribution

circuits. On this age of ship these are

generally confined to -

- Emergency lighting (throughout the ship)

- Transient lighting (control panels and operating

stations)

- Wireless telegraphy

- Small power (probably ventilation fans for

accommodation and other hotel services)

- Battery charging (main and “panic” banks)

Figure 3 rms EMPRESS OF BRITAIN Emergency switchboard

Figure 4 rms EMPRESS OF BRITAIN Emergency distribution system

iii Main diesel generating sets

The

vessel is fitted with four 450kW 225Vdc diesel generators situated in the

generator room between the after boiler room and the forward engineroom. These are large crosshead type engines, single-acting

and with blast (air) injection, as opposed to the modern methods of fuel

injection. A photo of one of the engines

is shown below.

Figure 5 rms EMPRESS OF BRITAIN One of the diesel generating sets

iv Turbo-Generator sets

In addition, there are two single-reduction

geared turbo-generators driven by BTH steam turbine prime movers at 6000rev/min,

each of 800kW 225Vdc. These sets are

situated on turbine flats, one either side of the forward engineroom bulkhead,

arranged longitudinally. The main and

auxiliary switchboards are situated in a switchboard room on E Deck, above the

diesel generator room.

Steam at a pressure of 375lb/in2 and

700F is fed to the turbines and exhaust steam is directed in port or at start

up to the auxiliary condensers. At sea

the exhaust steam is directed to the feed heaters to extract the remaining

energy from the exhaust steam and deliver it to the feed heating system. This configuration gives a total installed

power of 3.4MWdc, with adequate stand-by redundancy.

Without knowing the actual full load of the

vessel, the redundancy could be 2x100%, i.e. one turbine and two diesels (1.25MW)

or 4 diesels (1.8MW) or two turbines (1.6MW).

This sounds a reasonable load for such a ship, but the arrangement could

be any permutations depending on the load.

Whilst cruising on the centre shafts, the propulsion load would be less

and therefore the electrical load would also be less, though if air

conditioning was fitted for summer cruising, the additional load could take up

the reserve.

2. Starting the main diesel generating sets

Unlike the other ships in the series, the

fitting of main diesel generating sets only requires sufficient starting air to

get the main power up and running, so there is no need to start firing boilers

at this stage using the emergency sets.

If starting air is not available, the auxiliary starting air compressor

is started off the emergency supply and the starting air bottles charged

up. The main diesels are fitted with an

engine-driven seawater cooling pump for the jackets and oil coolers; not really

a good idea as seawater is highly corrosive, especially so at the running

temperature of a diesel. Nowadays

engines are cooled by a central fresh water system, which is in turn cooled by

raw seawater.

The engines are therefore self-contained,

with the fuel supply being gravity fed from the diesel oil service tanks

mounted on the generator room forward bulkhead.

Once the engine turns over on air and fires, the cooling and lube oil

systems start as they are also engine-driven.

A compressor on one end of the engine shaft generates compressed air for

the blast injection. The scavenge air

compressor (an early method of increasing the combustion air pressure prior to

the advent of turbo-charging) is mounted on the other end to balance the forces

and reduce vibration.

Main power is then available and the main

breakers are closed onto the main switchboard.

At this stage, all the power required for

starting the ship is available, with a turbo-generator being started once steam

is available. As the main switchboard

seems to be split with a turbo-generator and two diesels on each side of the

board (see Figure

7), we will only start two diesels (port inner and

outer) to give us 900kW of power available.

Below is a section through the diesel engine space showing the arrangement

of the engines 4 abreast, diesel tanks, air compressor and diesel transfer

pumps. Of interest are the spare

crankshaft and armature, probably carried for when the ship is cruising far

from her home ports.

Figure 6 rms EMPRESS OF BRITAIN Selection through auxilliary ER, looking forward

2.1 Main Switchboard distribution

The main switchboard is divided into sections

in order to distribute the power to the various areas of the ship. Most of the auxiliaries are electric drive

and the breakers for these can be seen on the board. On Direct Current the breakers for the

generators (all six are shown on the diagram) can be put straight on to the

board (with the shunt field regulator wound right down) - there is no need to

synchronise as with an alternating current system. The shunt field regulator is then wound up to

share the load with the other generators on the board. The board has two sections split by a bus-tie

breaker, which bears out the 2x100% redundancy in that a turbine generator is

seen on each side, paired with two diesel generators.

Of interest is the size of the Shore Power at

1,000A, corresponding to 225kW, and the 1500A Galley breakers corresponding to 337.5kW

– quite a large galley load as expected on a passenger ship of this size. If AC power had been available in 1931, the

electrical current load with a 3-phase 440V 60Hz supply would have been

considerably less, as the required power would result in a much lower current

and therefore a much reduced cable size and volt drop. For the same galley power of 337.5kW on an AC

supply, the current would be around 553A, approximately 37% of the dc current

shown.

An interesting note in a 1927 marine engineering

book states, “There is no foreseeable future for alternating current in

ships”. Fortunately, marine engineers

are forever endeavouring to achieve greater power and economy from the

machinery they design, have ignored that statement and alternating current is

now the standard in ships.

Figure 7 rms EMPRESS OF BRITAIN Main switchboard distribution

3 Firing up the boilers

We now have power available for the engineers

start the forced draught fans from the main switchboard.

Once the air is established the firemen start

an oil-fuel unit (electric drive) and light up the boilers, assuming there is

sufficient water level. If there isn’t

sufficient level, there are two sets of electrically driven auxiliary feed

pumps in the forward boiler room, which can be used to establish a level in all

the required boilers. It is likely that

there is also an electric “cold-start” feed pump in the engineroom, but this is

not shown on the drawings.

Once lit, dampers adjust the boiler draft and

the fires start to heat the water in the water-tube boilers. Water-tube boilers are much more efficient

and faster starting than fire-tube, but would still take around 7-10 hours to

raise steam to manoeuvring pressure from cold.

Firing boilers is carried out in stages to avoid thermal shock to the

tubes and boiler drums, with the superheater starting valve open, along with

the vents on top of the drums to dispel any air. Additionally the main stop on the first boiler

(usually furthest away, so in the forward boiler room) is open in order to

drain the main steam lines as pressure is raised.

As the pressure rises and steam is issuing

from the steam drum vents they are closed, with the superheater starting valve

left open to ensure a steam path through the superheater banks to avoid

damaging the tubes.

As steam is raised on the boiler which has

its main stop valve open, the drains along the whole length of the main steam

lines to the enginerooms are opened up to drain any condensate, as liquid

entering the turbine machinery can cause damage.

4 Main condensers and seawater circulating pumps

Once steam is raised and up to sufficient

pressure to start a turbo generator (around 375lb/in2) at the main

stops, the bulkhead stop valves to the main steam lines in the enginerooms are

opened to drain condensate from the lines serving the turbo-generators. The remaining main stop valves of the boilers

required to start a turbo-generator are cracked open to the main steam pipe and

the piping and valve drains opened to clear the lines of condensate, which can

damage reciprocating and turbine machinery.

Once steam is raised and is used, it has to

be returned to the boilers via the feed system.

It is not very clear from the simplified feed drawing in the book how

the feed system actually works regarding the exhausts from the turbo main feed

pumps (TMFP) or the exhausts from the turbo-generators. It can be reasonably assumed however, that

the auxiliary condenser situated on the starboard side of the forward boiler

room is both too far away and not large enough to handle either of the exhausts

from this machinery as in the earlier ships in this series, so the main

condensers will need to be put into service.

As a more modern ship, the main seawater

circulating pumps are electric drive, and there are 3 sets of 2 of these

fitted,

- one pair either side of the forward

engineroom thrust blocks

- one pair either side of the forward

engineroom underneath the turbo-generators

- one pair inboard of the centre shafting in

the after engineroom.

The

main circulating pumps for the inner shaft turbines are started and supply

seawater to the condensers under each turbine set, with the discharge sent

overboard. At the same time, and to

achieve the vacuum in the condenser by removing air and other non-condensables,

there are steam driven air ejectors fitted to all four turbine sets, the

forward engine room sets placed either side of the forward end of the turbines,

the after set inboard of the centre shafts in the after engineroom, serving the

two wing turbine condensers. These ejectors

use steam through a venturi arrangement to create a vacuum in the condensers.

Figure 8 rms EMPRESS OF BRITAIN One of the main SW circulating pumps and it´s starter (aft ER)

5 Starting a turbo-generator

We are now ready to start a turbo-generator

and will start the port turbo-generator, to serve with the two portside diesel

already on the board in accordance with the electrical schematic.

The exhaust from the turbine is opened to the

main condensers. As the turbo-generators

are in the forward engineroom, it is likely that the condensers under the inner

shaft turbines are used, not the after engineroom condensers, though there may

be bypass lines. The seawater passing

through these condensers condenses the exhaust steam into water, thereby

dropping its pressure and creating a vacuum.

Without this the turbine would trip on high exhaust backpressure, as the

exhaust steam has nowhere to go.

The turbine bearings are lubricated with oil,

so the stand-by LO pump is started and lubricating and control oil pressures

established. The control oil is used to

shut down the turbine in the event of LO pressure failure by holding open the

control valve whilst the pressure is maintained. Once the turbine is running, a shaft-driven

pump maintains the oil pressure. The oil

system is supplied with oil coolers and filters to maintain the temperature and

cleanliness within normal limits.

With all the lines drained to the turbine,

the stop valve is opened and the control valve drained through. Steam is now available right up to the

turbine inlet, and opening the throttle valve will allow the turbine to turn,

slowly gathering speed until it as full revolutions. The turbine sets incorporate single-reduction

gearing to reduce the electrical generator end speed to suit the supply

voltage.

The turbine control valve should now allow

itself to stay open unaided, held by the governor oil supply from the control

oil system. Speed control is therefore

automatic via the governor and the throttle valve. Usually the turbine trip is now tested, by

closing off the control oil to the throttle valve; loss of control oil pressure

should trip the valve. Once proved, the

system is reset and in operation.

Once up to speed, the generator main

switchboard breaker is closed and the shunt field regulator adjusted to share

the load with the two diesels. There is

now 1.7MW of power available for getting the ship underway.

As we are now consuming steam, we will also need

to start the main feed pumps to supply the boilers with feed water as required. The steam that is consumed by the

turbo-generator is being condensed as above into the condenser hotwell, and the

condensate extraction pumps (called “Pervac” pumps in the drawings) under the

condensers are started in order to maintain the correct condenser hotwell water

level. The feedwater and condensate

system is explained below.

6 The feed water and condensate system (see Figure 8)

The feed and condensate system is designed to

extract the maximum energy from the steam and return the heated feed back to

the boilers at the maximum design temperature.

Steam from the condensers that has condensed

into the hotwells under the condensers is returned to the boilers via two feed

heaters using the sets of condensate pumps (called “Pervac” pumps on the

drawing) located in a well below the tanktop and outboard of the lp turbines. These pumps deliver the condensate via the Drains Coolers located at the forward

end of the engineroom between the Forced LO pumps and their starters on the

forward bulkhead. These drains coolers

are fed with exhaust steam from the Primary Feed Heaters, mounted outboard in

each diesel generator room, and this exhaust heats the feedwater passing

through the shell and tube heating elements.

From the outlet of the drains coolers the

feed water is passed to the suction of the Turbo

Main Feed Pumps (TMFP), which are arranged in two sets of two pumps,

outboard at the forward end of the engineroom.

The TMFP then delivers the feed in series

through the Primary and Secondary Feed Heaters before delivery to the boiler

feed control valves. The secondary heaters

are also situated outboard in the diesel generator room, forward of the primary

units.

The Secondary

Heater is heated by bled steam from a turbine stage at 110lb/in2(a),

140F superheat and exhausts to the Primary Heater, along with some auxiliary

drains.

The Primary

Heater is also fed from a turbine stage at 30lb/in2(a) as well

as the exhaust from the Secondary Heater mentioned above, and exhausts to the

Drains Cooler as above, which in turn drains to the feed tanks mounted either

side on the forward bulkhead.

Appropriate recirculating piping is supplied to return feed water back

to the hotwell depending on boiler load conditions.

Of special

note in the feed arrangements for the forward engineroom (the after engineroom

is similar) are the Scotch boilers.

These have a set of feed pumps that draw from the Auxiliary Feed Tank

and discharge through the Auxiliary Feed Heater, termed “Greasy Exhaust Heater”

in the feed diagram. Auxiliary drains go

to this tank via the Auxiliary Condenser.

From the heater, the water is directed to the Scotch boilers, and the

“clean steam” so generated is delivered at 200lb/in2 to a turbine

stage. A line from this clean steam pipe

also leads to the auxiliary drains cooler, which supplies the heating medium

for the feed heater, whose drains are returned to the Auxiliary Feed Tank. All this equipment is situated outboard of

the starboard Scotch boiler in the forward boiler room. One can’t help wondering what these

contaminated drains do to the internals of the Scotch boilers, but it is

assumed that there is some kind of Observation Tank and filter to separate any

oily drains.

With everything up and running, steam is

raised on all the boilers required for leaving port.

Figure 9 rms EMPRESS OF BRITAIN The feed water and condensate system

7 Starting the main engines

We now have more than enough power for firing

all the boilers necessary for starting the main engines and getting the

enginerooms ready for sea.

First we have to get the propulsion exhaust

steam and feed systems arranged in a similar way to that of the generators,

with each turbine set more or less similar.

As the turbine sets are triple expansion, steam passes through each of the

hp, ip and lp stages and exhausts to the main condensers underneath the

turbines. For manoeuvring out of port,

only the forward engineroom sets are used, as they have astern turbines

configured in the set. The wing shaft

turbines are ahead capable only, and are therefore used to work up to full

speed on a transatlantic passage, and would be kept warmed through on “steam

spinning” until required. For cruising

the outer shafts have the propellers removed, so the turbines are not used for

this period, though the rotors will be turned regularly on the turning gear to

avoid sag.

7.1 Main engines (forward engine room)

By

this time the engineers (we assume we are not doing this on our own) will have

engaged the electric turning gear motors on all four shafts, as well as

starting the turbine motor-driven forced lube oil pumps arranged in sets of

three pumps forward of each of the two forward engineroom turbine sets. The oil filters and coolers are arranged aft

of the pumps.

Figure 10 rms EMPRESS OF BRITAIN The forced LO pumps in the forward (L) and aft (R) enginerooms

The engines are kept turning until required

for use, whence the gear is withdrawn to avoid damage to it in the event of

starting a turbine with it engaged.

Gland steam is assumed to have been fitted (no mention in the Engineer

& Shipbuilder reprint) and will be started up to extract leakage steam from

the turbine shaft glands, and condense it back to the hotwell drains. At this stage the turning gear is removed and

the engines turned on “steam spinning” ahead and astern to ensure all

condensate is drained and the turbines are ready for manoeuvring.

The turbines are kept warmed through ready

for manoeuvring and working up to speed on passage, with manoeuvring steam

admitted to the hp turbines with the drains full open until proved clear. In series, the exhaust steam from hp turbine

exhausts via the ip turbines and into the lp turbine sets. At first the main steam bulkhead stop valves

are cracked open until everything is warmed through, whence they can be fully

opened.

Once the turbine drains are emitting steam,

we can call the bridge and ask if the propellers are clear for a slow turn

ahead and astern on both inner shafts.

Once this is given, the turbine manoeuvring valves are set to the ahead

position (with the astern isolator closed) and the main steam regulating

control valve cracked open at the starting platform at the forward end of the

turbine room. Each engine turns ahead at

low revs. After a few turns of the

shafts ahead the regulating valve is closed and the astern isolator opened to

allow steam to the astern turbines on each shaft. Again the regulating valve is cracked open

and the astern hp turbine turns, with its exhaust to the ip astern turbine and

the ip exhaust to the lp astern turbines.

The shafts turn astern for a few revs at low speed.

We are about ready to go, and test the

communications between the engineroom, boiler rooms and bridge so that we are

ready for sea service. Around the same

time an engineer is dispatched to the steering engine room to warm start the

steering motors and test the rudder from midships to 30 degrees port, back to

30 degrees starboard then returning to midships.

Figure 11 rms EMPRESS OF BRITAIN Gauge panel at forward end of the turbines

8 Getting under way

In

response to the bridge signals on the engineroom telegraphs, the ahead/astern turbine

sets are manoeuvred accordingly as above and the ship departs her berth and

heads for the open sea.

8.1 High-pressure and intermediate-pressure turbines

Once the ship is up to full ahead, and prior

to full away, the steam is now passing from the boilers to the main steam

lines, through the hp turbines, into the lp turbines, then the lp turbines and

finally exhausting to the condensers, from where it is returned to the boilers

as above in a closed feed cycle.

On transatlantic service, the after engineroom

is now engaged and the outboard turbines and feed system put into service. Full power can now be worked up once full

away is rung on the telegraphs.

8.2 The starting plattforms

The

main engines and some of the auxiliaries such as the steering gear are started

from the Starting Platforms, of which there are one for each engineroom.

Figure 12 rms EMPRESS OF BRITAIN The forward ER starting plattform

At the after end of the platform are the

turbine manoeuvring valves, where the engineers stand facing the engines –

looking aft. The three main wheels shown

are the Astern Master Valve (sometimes called the Astern Isolator), which

physically stops astern steam being applied if the ahead wheel is open. Next is the Astern Manoeuvring Valve which,

providing the Master Valve is open, applies steam to the astern turbines. The outboard wheel is the Ahead Manoeuvring

Valve, which turns the ahead turbines.

Once Full Away rings off stand-by, the ahead valve is gradually opened

up until the turbines are at full speed ahead.

Various telegraphs are also shown for both engines and boiler rooms.

The Water Spray Controls shown are for

manually spraying water into the condenser to force the water level and improve

the vacuum when manoeuvring.

On the forward bulkhead are the isolators for

the after engineroom steam system, and the Forced LO control panels above the

drains coolers, shown in the photo below.

Figure 13 rms EMPRESS OF BRITAIN Speed regulators and ammeters for FL pumps

8.3 Aft engineroom starting plattform

Figure 14 rms EMPRESS OF BRITAIN Aft ER / engine room starting plattform

As

the after engineroom turbines are not used during manoeuvring, the controls

here are much simplified. A voice pipe

from the forward starting platform relays orders as required to the after

personnel. As the after engineroom

handles the outboard engines – which do not have astern running – the engines

are brought up to speed once full away is rung, but opening the main steam

shutoff valves either side of the drains cooler. Telegraphs, revolution counters, feed gauges

and a FL Pump panel similar to the forward station are provided.

Plates from the

publication “Ocean Liners of the Past,

Empress of Britain (1931)

(With notes to explain the various items of

equipment fitted)

Figure 15 rms EMPRESS OF BRITAIN Elevation and plan of boiler rooms up to the ER bulkhead

9 Profile and plan of boiler rooms

On the view in Figure 15 can be seen the extent of the forward

and aft boiler rooms. The Yarrow boilers

are installed 6 in the after boiler room, and the remaining 2 in the forward

boiler room.

Also shown in the forward boiler room are the

two Scotch boilers either side of the innovative Johnson boiler in the centre.

9.1 Uptakes

The

uptakes can clearly be seen, illustrating that the forward two funnels on this

vessel served the boilers with the aft funnel serving as a ventilation shaft

and engine hatch over the enginerooms.

9.2 Fuel oil tanks

Between

the two boiler rooms are the boiler fuel oil tanks, consisting of four storage

tanks and four settling tanks, with an access way between. Situated in the access way are the watertight

door hydraulic pumps.

9.3 Oil fuel units

Between each pair of Yarrow boilers can be

seen an oil-fuel unit. There is also one

unit inboard of the port Scotch boiler which serves the two boilers. Either this unit or more likely the one shown

adjacent to the evaporators on the port side would supply the Johnson boiler.

These units contain supply pumps, which draw

from the settling tanks, then pass the fuel through strainers and filters to

clean it before supplying it to the boiler burners.

9.4 Other auxilliary units

The Scotch boilers are used to evaporate raw

feed water, the steam produced being passed to an intermediate stage of the

main turbines. In the forward boiler

room can be seen two evaporators to make feedwater from seawater, and also a

distiller for producing feed water from condensed steam and/or fresh

water. An auxiliary condenser, pumps and

feed tank for serving the Scotch boilers is shown on the starboard side.

In the aft boiler room is an Oily Water

Separator, used to clean bilge water before discharge overboard. These were early units which made a token

attempt to clean the water, compared to the strict regulations nowadays on

marine pollution as published by the MARPOL guide which limits overboard

discharges to 15ppm oil in water.

Figure 17 rms EMPRESS OF BRITAIN Elevation of engine rooms

Figure 18 rms EMPRESS OF BRITAIN Plan of engine rooms

10 Elevation and plan of the enginerooms

The views in Figure 17 and Figure 12 show the forward and after enginerooms.

10.1 Diesel generator room

Starting at the forward end of the Diesel

Generator Room are the diesel service

tanks (treated fuel from the settling tanks located between the two boiler

rooms) plus some other smaller day tanks.

These supply clean fuel for the engines.

Next are the engines themselves, with the

Primary and Secondary Feed Heaters shown.

Note the spare generator crankshaft, which in

modern ships is not a capital spare item.

In 1931 perhaps even on a transatlantic voyage, the steam engineers

didn’t trust a diesel generator; this is often the case with steam engineers

even today!

10.2 Forward engine room

Passing through the door at the after end of

the diesel generator room, we enter the forward engineroom.

On the forward bulkheads can be seen the

feedwater tanks (called Hotwell tanks on the drawing), the Forced LO pumps and

their attendant oil coolers.

Above is the starting platform, the drains

coolers (against the forward bulkhead), air ejectors and the entrance to the

switchboard room over the diesel generator room. Also shown is a manoeuvring gear stand and

above this space the forced LO gravity tank which supplies LO by gravity if the

forced LO pumps fail, timed to give enough LO for the turbines to run down.

Moving aft, the turbine sets, condensers,

“Pervac Pumps” situated in a well, three General Service pumps and a distilled

water header tank are shown.

Under the turbines in the double bottom are

the Forced Lube drain tanks, and cofferdams.

The turbine thrust blocks are shown, as are

the centre shaftlines exiting through the watertight bulkhead into the after

engineroom.

Above the machinery can be seen ventilation fans

for the enginerooms.

10.3 Aft engine room

In this room are the wing turbines,

condensers and auxiliaries for the turbine operation.

Starting at the forward bulkhead, the inner

shafts can be seen exiting through the bulkhead and passing through the space.

On the centreline is the hotwell tank (feed

tank), Drains Cooler and Feedwater Filters.

Outboard are two distilled water tanks, one on each side. Either side of the centreline are the Primary

and Secondary Feed Heaters for the after feed system.

Moving aft are the outer shaft wing turbines,

on the centreline are the TMFP for the after feed system and between the inner

shafts are the steam air ejectors, the “Pervac” pumps (condensate pumps) and a

Fresh Water pump.

Aft of these and still within the inner

shafts are the Forced Lube pumps mounted on the FL tank on the centreline, the

two main seawater circulating pumps and two general service pumps. Above is a switchboard.

Mounted outboard of the engineroom are two

calorifiers for heating domestic water and two swimming pool filtration units

on the port after bulkhead.

From this area, the four shafts exit to the

shaft tunnels.

10.4 Shafting and propellers

The two inner propulsion shafts are arranged

in the shaft tunnels and exit the ship via the stern tubes. There are several intermediate bearings

(Plummer Blocks) along the length of the shafting, which are splash lubricated.

The outer pair of shafts exit the hull in pods

which are supported by shaft brackets to the hull structure.

Figure 19 Shaft of a large liner

Comments

Post a Comment