Environmental regulations imposed on

operators means that they must adopt new technology to comply with the new

rules. In many cases the choice is LNG or low sulphor HFO or MDO.

by Earl of Cruise, based on THE NAVAL ARCHITECT, October 2016

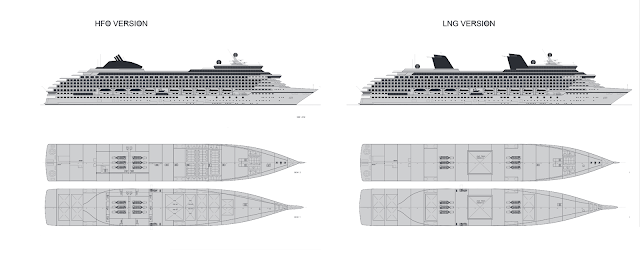

Cruise vessel design of KNUD E. HANSEN - courtesy KNUD E. HANSEN

Danish naval architects, KNUD E.

HANSEN takes an informed look at the merits and demerits of both fuels,

LNG and HFO, on a medium sized cruise liner. The naval architects have

designed a medium sized cruiseship, ostensibly for a Greek operator to

deploy in the Mediterranean. But KNUD E. HANSEN have made a comparison

between the HFO fuelled version and its LNG variant.

According to KNUD E. HANSEN´s comparison,

the operating expenses for the LNG version are lower, including the fuel

consumption when the scrubber fuel (HFO) consumption is included in

the calculation.

Scrubbers take out SOx from the

exhaust when vessels are operating in Environmental Control Areas (ECA).

These are f.e. 200sm off coast North America, the British Chanel, the North Sea,

Baltic Sea and as well in Polar Regions. The Mediterranean is soon to follow,

as well the Caribbean.

IMO regulation say the step will be

in 2020, years ahead of the once planed schedule. Fuel has to be with at best 0,1%

to a maximum of 0,5% sulphor.

LNG–fuelled ships will not

need scrubbers to meet the SOx rules. On the other side all conventional

fuelled ships need scrubbers to pass the new regulations. The LNG–fuelling is

cutting back on both capital expenditue and operating costs. Further

space is safed within the ship, or for the funnel design (dimensions). In

addition, the LNG ships will not need a selective catalytic reduction

(SCR) to meet NOx rules, while HFO heating and purifying equipment

would be unnecessary. HFO needs to be heated to around 60° to become

"a fluid".

Furthermore, there would be no need

for settling and daily tanks for the fuel and no waste

chemicals.

Gas carriers often take advantage

of boil-off gas. LNG is stored in liquid form at -163°C and will emit

small amounts of gas as the liquid warms. This boil-off gas is used

for powering the main engine. But a cruise vessel can take advantage of this boil-off

rate to cover the higher demands in electric load in the hotel section

of the vessel.

In these days where safety is an

issue as well as the availability of LNG in some parts of the world,

the ability to switch fuels offers the cruise operator an `extra degree of redundancy´,

explains KNUD E. HANSEN. The design company also explained that

the LNG version prompted them to explore more innovative solutions in

terms of engine room and consequently funnel location.

Such solutions, however, are

no longer unique to the LNG fueled vessel.

Each new construction has to consider

the new IMO machinery system redundancy requirements of the INO - SAFE RETURN to

PORT RULE, e.g. two sperated machine rooms. Similar arrangements are now

feasible for any diesel-electric configuration with only limited

impact on construction costs.

And the final advantage

according to KNUD E. HANSEN is that the bunkering process can take place

with passengers onboard saving time in the operation of the ship.

The list of disadvantages is

shorter, but could ultimately prove more costly, at least in the

short term.

Higher capital expenditure will

be needed to build the vessel with all the safety features necessary

for using a low flashpoint fuel. Safety will necessarily be a

significant issue and the crew will need special training in the use

of equipment and the handling of LNG.

In addition, the LNG

tank arrangement uses up a lot of technical space. Membrane tanks

negate this effect compared to other types of tanks such as Type C

tanks, while the LNG tank structure adds up a considerable amount of

weight.

LNG fuelled cruise vessel design of KNUD E. HANSEN - courtesy KNUD E. HANSEN

Depicting the new configuration for LNG fuelled cruise ships

Strict bunkering procedures

require the isolation of the main fire zone (MFZ) although there are `no

official regulations regarding the bunkering procedure, only

universally accepted guidance´, explains the design company.

Bunkering LNG itself could also

prove a difficulty in some parts of the world.

LNG supply and infrastructure

remains underdeveloped. Meanwhile, a lack of experience in the design

and operation of LNG powered cruise vessels means that investors

are reluctant to risk being the first to make the investment. Tank

sizing was based on three operational scenarios. In all three of

them there is the assumption that the energy requirements of the

vessel can be covered relying solely on either LNG or HFO.

Technical Particulars - Reference

vessel

Loa

|

250m

|

Breadth

|

034m

|

Depth

|

009.5m

|

Design draught

|

007m

|

Service Speed

|

18 Kn

|

Persons onboard

|

2650 (passenger and crew)

|

Propulsion

|

podded electric thrusters

|

LNG Version

|

6 medium speed dual fuel engines.

LNG as main fuel, in combination

with MDO for pilot fuel and compliance with SRtP rules.

Membrane type of tank for LNG

storage HFO Version 6 medium speed diesel generators HFO in all normal

operating conditions Scrubbers and possible SCR/EGR

|

KNUD E. HANSEN research results are

as follows:

Scenario 1

|

includes five day

cruises, with four trips per month and bunkering intervals at 14

days

|

Scenario 2

|

has 2.5 trips a month with

12-day cruises and bunkering intervals set at six-12 days

|

Scenario 3

|

includes a

21-day transatlantic cruise, 1.4 trips per month, and bunkering

intervals of every 10 days.

|

The outcome of this research

was that an LNG tank of 2,000m³, would be sufficient to cover the

vessel’s needs for the first 2 scenarios, while for the third one,

a future retrofit and potential addition of a tank could be an

option.

HFO fuelled cruise vessel design of KNUD E. HANSEN - courtesy KNUD E. HANSEN

Depicting the "classic" configuration for modern day cruise vessels

The pilot fuel has been calculated

as the equivalent to 5% of the LNG thermal capacity that is onboard.

Additional MDO to comply with the safe return to port rules and for

redundancy purposes would also need to be taken into account.

For the two versions of the

cruiseship design there are potentially small changes in the

dimensions of the vessels midship section. The vessel will include two engine

rooms located fore and aft of the LNG tanks. A reduction on the amount

of equipment that will be required in the LNG version offers the

possibility of rearranging the machinery area to gain space.

This will also necessitate

changes to the crew cabins location, the crew public spaces and the provisions

area. A change in the vessel’s profile due to double funnels, located

on the centreline of the machine room will also mean changes to the

external open deck arrangement and facilities that would be combined with

the two funnels.

On the LNG version the membrane tanks

are preferred as these types of tank use the available space more

efficiently.

According to the naval architect: "80% of the vessel’s inner hull volume in the certain compartment that will accommodate the membrane, will constitute the membrane. There is a difference of 30-40% in the usable volume of the area where the tank is located between Type C and membrane tanks."

In addition, there is "no minimum filling limit in membrane tanks (no thermal stresses restrictions as in type C tanks)".

According to the naval architect: "80% of the vessel’s inner hull volume in the certain compartment that will accommodate the membrane, will constitute the membrane. There is a difference of 30-40% in the usable volume of the area where the tank is located between Type C and membrane tanks."

In addition, there is "no minimum filling limit in membrane tanks (no thermal stresses restrictions as in type C tanks)".

Irrespective of the type of

tanks, cruiseships can turn the potential problem of boil off gas to

an advantage through the powering of the hotel areas. "Managing the boil-off gas on a

cruise vessel is not considered a major issue, due to the extended

hotel load," says KNUD E. HANSEN. "Often, boil-off gas is produced on purpose to cover the

needs in electrical load."

When this is not the case, the `excess´ boil-off

gas can be used in various ways, including the innovative combination

of an LNG fuelled vessel with significant battery storage onboard.

The boil-off gas can be used for battery charging via DC electric

storage, increasing the LNG efficiency onboard while offering a

further more eco-friendly solution.

The excess gas can also be used to

fuel the auxiliary boiler and produce steam for various purposes or to

fuel the incinerator. Other solutions, including gas

combustion units, which just waste the energy, and reliquefaction units,

are costly and apply mostly to other, more specialised types

of vessel such as gas carriers. These are not neccessary for cruise

vessels.

Comments

Post a Comment